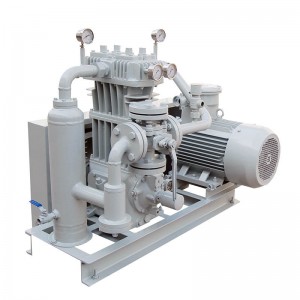

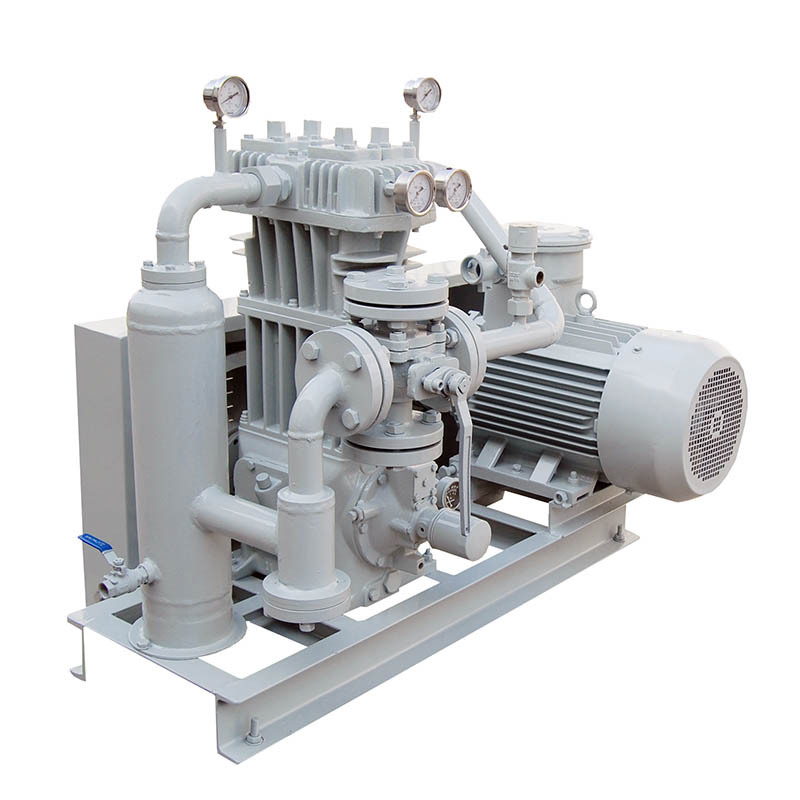

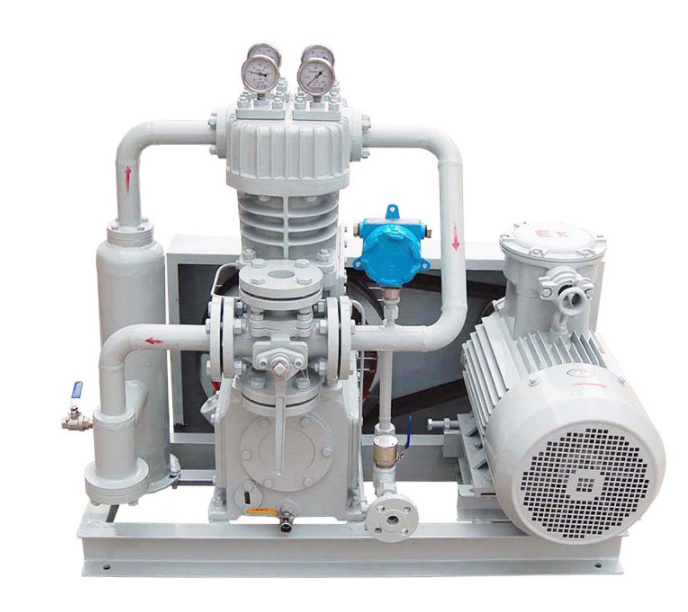

Ammonia LPG unloading compressor

Ammonia LPG unloading compressor

Product Description

This series of oil-free lubrication compressors is one of the products produced by our company. The product has the characteristics of low rotation speed, high component strength, stable operation, long service life, and convenient maintenance. Among them, the ZW series compressor is in the form of a unit. It integrates a compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, check valve, explosion-proof motor, and chassis. It has the characteristics of small size, lightweight, low noise, good airtightness, easy installation, and simple operation.

This product is mainly used for unloading, loading, refilling, gas recovery, and residual liquid recovery of LPG/C4, propylene, and liquid ammonia. It is widely used in gas, chemical, energy, and other industries, and is the key equipment for gas, chemical, energy, and other industries.

Note: In the process of unloading, the compressor pressurizes the gas from the storage tank and then presses it into the tank truck through the gas phase pipeline, and presses the liquid from the tank truck to the storage tank through the pressure difference of the gas phase to complete the unloading process. When the gas phase is pressurized, the temperature of the gas phase will increase. At this time, it is not necessary to perform forced cooling, because if the gas phase is compressed and then cooled, it is easy to liquefy and it is difficult to establish a pressure difference in the gas phase, which is not conducive to the replacement of the gas phase and the liquid phase. In short, it will cause an extension of the unloading process time. If residual gas recovery is required, a cooler can be used to forcibly cool the gas phase during the residual gas recovery operation in order to recover the residual gas as soon as possible.

The loading process is opposite to the unloading process.

|

NO |

Model |

(Nm3/h) |

Inlet pressure (Mpa) |

Outlet pressure (Mpa) |

Moter POWER (KW) |

Dimensions (mm) |

|

1 |

ZW-0.6/16-24 |

550 |

1.6 |

2.4 |

11 |

1000×580×870 |

|

2 |

ZW-0.8/16-24 |

750 |

1.6 |

2.4 |

15 |

1000×580×870 |

|

3 |

ZW-1.0/16-24 |

920 |

1.6 |

2.4 |

18.5 |

1000×580×870 |

|

4 |

ZW-1.5/16-24 |

1380 |

1.6 |

2.4 |

30 |

1000×580×870 |

|

5 |

ZW-2.0/16-24 |

1500 |

1.6 |

2.4 |

37 |

1000×580×870 |

|

6 |

ZW-2.5/16-24 |

1880 |

1.6 |

2.4 |

45 |

1000×580×870 |

|

7 |

ZW-3.0/16-24 |

2250 |

1.6 |

2.4 |

55 |

1000×580×870 |

|

8 |

ZW-0.8/10-16 |

450 |

1.0 |

1.6 |

11 |

1100×740×960 |

|

9 |

ZW-1.1/10-16 |

600 |

1.0 |

1.6 |

15 |

1100×740×960 |

|

10 |

ZW-1.35/10-16 |

750 |

1.0 |

1.6 |

18.5 |

1100×740×960 |

|

11 |

ZW-1.6/10-16 |

950 |

1.0 |

1.6 |

22 |

1400×900×1180 |

|

12 |

ZW-2.0/10-16 |

1200 |

1.0 |

1.6 |

30 |

1400×900×1180 |

|

13 |

ZW-2.5/10-16 |

1500 |

1.0 |

1.6 |

37 |

1400×900×1180 |

|

14 |

ZW-3.0/10-16 |

1800 |

1.0 |

1.6 |

45 |

1400×900×1180 |

|

15 |

ZW-0.6/16-24 |

550 |

1.6 |

2.4 |

11 |

1500×800×1100 |

|

16 |

ZW-0.8/16-24 |

750 |

1.6 |

2.4 |

15 |

1500×800×1100 |

|

17 |

ZW-1.0/16-24 |

920 |

1.6 |

2.4 |

18.5 |

1500×800×1100 |

|

18 |

ZW-1.5/16-24 |

1380 |

1.6 |

2.4 |

30 |

1600×900×1200 |

|

19 |

ZW-2.0/16-24 |

1500 |

1.6 |

2.4 |

37 |

1600×900×1200 |

|

20 |

ZW-2.5/16-24 |

1880 |

1.6 |

2.4 |

45 |

1600×900×1200 |

|

21 |

ZW-3.0/16-24 |

2580 |

1.6 |

2.4 |

55 |

1600×900×1200 |

|

22 |

ZW-3.5/16-24 |

3000 |

1.6 |

2.4 |

55 |

1600×900×1200 |

|

23 |

ZW-4.0/16-24 |

3500 |

1.6 |

2.4 |

75 |

1600×900×1200 |

|

24 |

ZW-0.2/10-25 |

100 |

1 |

2.5 |

5.5 |

1000×580×870 |

|

25 |

ZW-0.4/10-25 |

220 |

1 |

2.5 |

11 |

1000×580×870 |

|

26 |

ZW-0.6/10-25 |

330 |

1 |

2.5 |

15 |

1000×580×870 |

|

27 |

ZW-0.2/25-40 |

260 |

2.5 |

4 |

7.5 |

1000×580×870 |

|

28 |

ZW-0.4/25-40 |

510 |

2.5 |

4 |

15 |

1000×580×870 |

|

29 |

ZW-0.5/25-40 |

660 |

2.5 |

4 |

18.5 |

1000×580×870 |

|

30 |

ZW-0.3/20-30 |

300 |

2 |

3 |

7.5 |

1000×580×870 |

|

31 |

ZW-0.4/20-30 |

420 |

2 |

3 |

11 |

1000×580×870 |

|

32 |

ZW-0.5/20-30 |

540 |

2 |

3 |

15 |

1000×580×870 |

|

33 |

ZW-0.6/20-30 |

630 |

2 |

3 |

15 |

1000×580×870 |

|

34 |

ZW-1.6/20-30 |

1710 |

2 |

3 |

37 |

1400×900×1180 |

After Sales Service

1. Quick response within 2 to 8 hours, with a reaction rate exceeding 98%;

2. 24-hour telephone service, please feel free to contact us;

3. The whole machine is guaranteed for one year (excluding pipelines and human factors);

4. Provide consulting service for the service life of the whole machine, and provide 24-hour technical support via email;

5. On-site installation and commissioning by our experienced technicians;

1.How to get a prompt quotation of a gas compressor?

1)Flow Rate/Capacity: ___ Nm3/h

2)Suction/ Inlet Pressure: ____ Bar

3)Discharge/Outlet Pressure:____ Bar

4)Gas Medium:_____

5)Voltage and Frequency : ____ V/PH/HZ2.How long is delivery time ?

Delivery time is around the 30-90 days .3.What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquire.

4.Can you accept OEM orders?

Yes, OEM orders is highly welcome.

5.Will you provide some spare parts of the machines?

Yes, we will .