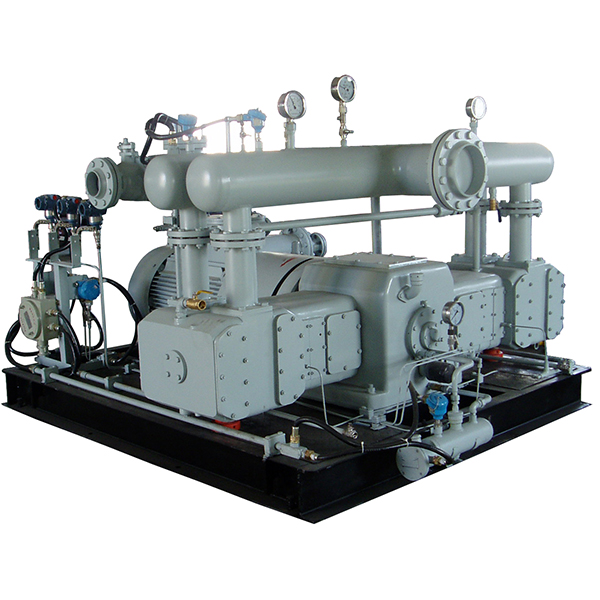

China High quality Nitrogen Booster Supplier – LNG-BOG Piston Compressor for Natural Gas Station – Huayan

China High quality Nitrogen Booster Supplier – LNG-BOG Piston Compressor for Natural Gas Station – Huayan Detail:

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| GZ series diaphragm compressor parameter table | ||||||||

| Model | Cooling water consumption (t/h) | Displacement (Nm³/h) | Intake pressure (MPa) | Exhaust pressure (MPa) | Dimensions L×W×H(mm) | Weight (t) | Motor Power (kW) | |

| 1 | GZ-2/3 | 1.0 | 2.0 | 0.0 | 0.3 | 1200×700×1100 | 0.5 | 2.2 |

| 2 | GZ-5/0.5-10 | 0.2 | 5.0 | 0.05 | 1.0 | 1400×740×1240 | 0.65 | 2.2 |

| 3 | GZ-5/13-200 | 0.4 | 5.0 | 1.3 | 20 | 1500×760×1200 | 0.75 | 4.0 |

| 4 | GZ-15/3-19 | 0.5 | 15 | 0.3 | 1.9 | 1400×740×1330 | 0.75 | 4.0 |

| 5 | GZ-30/5-10 | 0.5 | 30 | 0.5 | 1.0 | 1400×740×1330 | 0.7 | 3.0 |

| 6 | GZ-50/9.5-25 | 0.6 | 50 | 0.95 | 2.5 | 1500×760×1200 | 0.75 | 5.5 |

| 7 | GZ-20/5-25 | 0.6 | 20 | 0.5 | 2.5 | 1400×760×1600 | 0.65 | 4.0 |

| 8 | GZ-20/5-30 | 1.0 | 20 | 0.5 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| 9 | GZ-12/0.5-8 | 0.4 | 12 | 0.05 | 0.8 | 1500×760×1200 | 0.75 | 4.0 |

| 10 | GZ—5/0.5-8 | 0.2 | 5.0 | 0.05 | 0.8 | 1400×740×1240 | 0.65 | 2.2 |

| 11 | GZ-14/39-45 | 0.5 | 14 | 3.9 | 4.5 | 1000×460×1100 | 0.7 | 2.2 |

| 12 | GZ-60/30-40 | 2.1 | 60 | 3.0 | 4.0 | 1400×800×1300 | 0.75 | 3.0 |

| 13 | GZ-80/59-65 | 0.5 | 80 | 5.9 | 6.5 | 1200×780×1200 | 0.75 | 7.5 |

| 14 | GZ-30/7-30 | 1.0 | 30 | 0.7 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| 15 | GZ-10/0.5-10 | 0.2 | 10 | 0.05 | 1.0 | 1400×800×1150 | 0.5 | 4.0 |

| 16 | GZ-5/8 | 0.2 | 5.0 | 0.0 | 0.8 | 1400×800×1150 | 0.5 | 3.0 |

| 17 | GZ-15/10-100 | 0.6 | 15 | 1.0 | 10 | 1400×850×1320 | 1.0 | 5.5 |

| 18 | GZ-20/8-40 | 1.0 | 20 | 0.8 | 4.0 | 1400×850×1320 | 1.0 | 4.0 |

| 19 | GZ-20/32-160 | 1.0 | 20 | 3.2 | 16 | 1400×850×1320 | 1.0 | 5.5 |

| 20 | GZ-30/7.5-25 | 1.0 | 30 | 0.75 | 2.5 | 1400×850×1320 | 1.0 | 7.5 |

| 21 | GZ-5/0.1-7 | 1.0 | 5.0 | 0.01 | 0.7 | 1200×750×1000 | 0.6 | 2.2 |

| 22 | GZ-8/5 | 1.0 | 8.0 | 0.0 | 0.5 | 1750×850×1250 | 1.0 | 3.0 |

| 23 | GZ-11/0.36-6 | 0.4 | 11 | 0.036 | 0.6 | 1500×760×1200 | 0.75 | 3.0 |

| 24 | GZ-3/0.2 | 1.0 | 3.0 | 0.0 | 0.02 | 1400×800×1300 | 1.0 | 2.2 |

| 25 | GZ-80/20-35 | 1.5 | 80 | 2.0 | 3.5 | 1500×800×1300 | 0.9 | 5.5 |

| 26 | GZ-15/30-200 | 1.0 | 15 | 3.0 | 20 | 1400×1000×1200 | 0.8 | 4.0 |

| 27 | GZ-12/4-35 | 1.0 | 12 | 0.4 | 3.5 | 1500×1000×1500 | 0.8 | 5.5 |

| 28 | GZ-10/0.5-7 | 0.4 | 10 | 0.05 | 0.7 | 1500×760×1200 | 0.75 | 3.0 |

| 29 | GZ-7/0.1-6 | 1.0 | 7.0 | 0.01 | 0.6 | 1200×900×1200 | 0.8 | 3.0 |

| 30 | GZ-20/4-20 | 1.0 | 20 | 0.4 | 2.0 | 1400×850×1320 | 0.75 | 2.2 |

| 31 | GZF-42/120-350 | 1.2 | 42 | 12 | 35 | 900×630×834 | 0,42 | 5.5 |

| 32 | GZ-7/0.1-6 | 1.5 | 7 | 0.01 | 0.6 | 1200×900×1200 | 0.8 | 3.0 |

| 33 | GZ-120/80-85 | 1.5 | 100 | 8.0 | 8.5 | 1200×900×1200 | 0.8 | 4.0 |

| 34 | GZ-5/6-10 | 1.0 | 5.0 | 0.6 | 1.0 | 1200×700×1100 | 0.7 | 2.2 |

| 35 | GZ-7/50-350 | 1.0 | 7.0 | 5.0 | 35 | 1150×700×1100 | 0.45 | 3.0 |

| 36 | GZ-20/7-30 | 1.0 | 20 | 0.7 | 3.0 | 1400×760×1100 | 0.75 | 4.0 |

| 37 | GZ-62/40-56 | 1.5 | 62 | 4.0 | 5.6 | 1200×700×1100 | 0.45 | 3.0 |

| 38 | GZ-15/10-12 | 1.5 | 15 | 1.0 | 1.2 | 1200×700×1100 | 0.5 | 3.0 |

| 39 | GZ-14/6-20 | 1.0 | 14 | 0.6 | 2.0 | 1200×700×1100 | 0.5 | 2.2 |

| 40 | GZ-350/120-450 | 1.0 | 350 | 5-20 | 450 | 2350×1850×1100 | 7.0 | 37 |

| 41 | GZ-936/8-8.3 | 2.0 | 936 | 0.8 | 0.83 | 2100×1500×1700 | 2.0 | 15 |

GZ diaphragm compressor|nitrogen diaphragm compressor|hydrogen sulfide diaphragm compressor|is an all-non-standard compressor product in the industry, GZ diaphragm compressor is single-cylinder first-stage diaphragm compressor, GZ series compressor Covering different piston forces from small to large, the price of GZ products varies greatly depending on the configuration range, ranging from tens of thousands to hundreds of thousands. It can be customized according to different customer parameters, requirements and environment!

GZ diaphragm compressor is composed of cylinder block, cylinder head, crankshaft connecting rod, diaphragm, oil circuit, gas path, water cooling system and motor drive. All diaphragm compressor series products can provide various cooling. Mode: air cooling, water cooling and forced cooling.

Diaphragm compressors are one of many types of compressors. Because of its special diaphragm, the compressed gaseous medium is named after the outside (hydraulic oil, piston). The diaphragm compressor can also be referred to simply as a membrane compressor. Due to its special structure, the diaphragm compressor does not need lubrication, and the sealing performance is very good. The compression medium is not in contact with any slip agent, so it can compress the gas with very high purity, generally achieving a purity of 99.999%, which is more suitable for compression. And transport all kinds of precious rare gases. In addition, for corrosive, radioactive, toxic, and explosive gases, diaphragm compressors are also particularly suitable. The diaphragm compressor has good heat dissipation and can adopt a high compression ratio, so its pressure range is wide, and the exhaust pressure can be up to 50MPa. It is used in the food industry, petroleum industry chemical industry, electronics industry, nuclear power plant, aerospace, military equipment, medicine, scientific research and other fields.

However, the main disadvantages are that the dome-shaped surface of the cover plate is a special profile, which is difficult to process; the price is higher than other types of compressors.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for China High quality Nitrogen Booster Supplier – LNG-BOG Piston Compressor for Natural Gas Station – Huayan , The product will supply to all over the world, such as: Pretoria, Hungary, Muscat, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

A good manufacturers, we have cooperated twice, good quality and good service attitude.