CNG Filling Station Compressor

Low Pressure and High Pressure CO2 compressor

CNG compressor is a device used for compressing natural gas (CNG), which has the characteristics of high stability, wide pressure range and high efficiency and energy saving.

CNG compressor is mainly used to compress natural gas to the pressure required for storage and transportation.

The key features of this type of compressor include:

1. High stability : Ensure the reliability and safety of the CNG compression process.

2. Wide pressure range : Can adapt to different application requirements, the pressure can reach 25MPa.

3. Motor power : From 18.5kW to 350kW, Adapt to applications of different scales

4. Energy-saving design: Reduce energy consumption and improve energy efficiency through advanced energy-saving technologies.

In addition, CNG compressors are available in various types, including fixed, mobile and skid-mounted, to meet different usage scenarios and installation requirements. Based on factors such as cooling method, number of compression stages, number of cylinders, etc..

CNG compressors can be divided into various types, such as water-cooled, air-cooled, single-stage, double-stage, multi-stage, etc., as well as single-cylinder, double-cylinder, multi-cylinder configurations. These classifications provide flexible options to meet specific application conditions.

In CNG filling stations, CNG compressors work together with other key equipment such as high-pressure gas storage systems, gas measurement and control systems, gas purification systems, and safety protection systems to ensure the safe and efficient operation of CNG filling stations. The selection and configuration of these equipment and systems requires optimized design based on factors such as the scale, usage requirements, and safety requirements of the filling station.

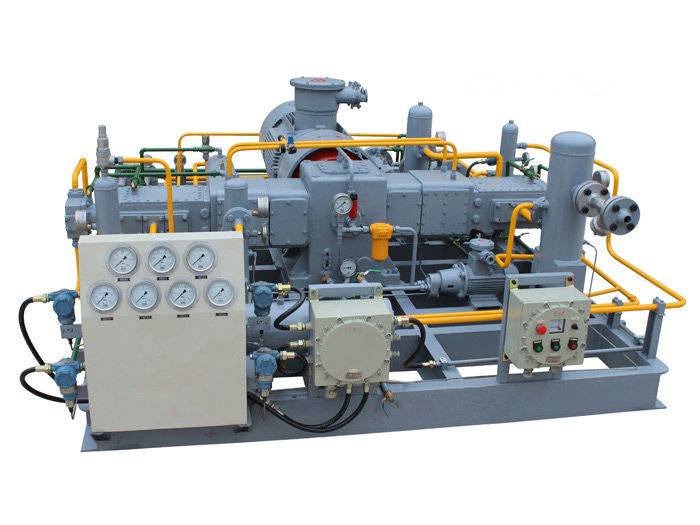

The unit consists of a compressor host, electric motor, coupling, flywheel, pipeline system, cooling system, electrical equipment, and auxiliary equipment.

The CNG compressor series produced by our company have the advantages of stable operation, large exhaust volume, low exhaust temperature, wide application range, low failure rate, safe and reliable use, and low maintenance cost, and are suitable for use in CNG standard stations.

Certificates

HYDROGEN COMPRESSOR-PARAMETER TABLE

|

Number |

Model |

Flow-rate(Nm3/h) |

Inlet pressure(Mpa) |

Exhaust pressure(Mpa) |

Medium |

Motor power(kw) |

Overall dimensions(mm) |

|

1 |

ZW-0.5/15 |

24 |

Normal pressure |

1.5 |

Hydrogen |

7.5 |

1600*1300*1250 |

|

2 |

ZW-0.16/30-50 |

240 |

3 |

5 |

Hydrogen |

11 |

1850*1300*1200 |

|

3 |

ZW-0.45/22-26 |

480 |

2.2 |

2.6 |

Hydrogen |

11 |

1850*1300*1200 |

|

4 |

ZW-0.36 /10-26 |

200 |

1 |

2.6 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

5 |

ZW-1.2/30 |

60 |

Normal pressure |

3 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

6 |

ZW-1.0/1.0-15 |

100 |

0.1 |

1.5 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

7 |

ZW-0.28/8-50 |

120 |

0.8 |

5 |

Hydrogen |

18.5 |

2100*1350*1150 |

|

8 |

ZW-0.3/10-40 |

150 |

1 |

4 |

Hydrogen |

22 |

1900*1200*1420 |

|

9 |

ZW-0.65/8-22 |

300 |

0.8 |

2.2 |

Hydrogen |

22 |

1900*1200*1420 |

|

10 |

ZW-0.65/8-25 |

300 |

0.8 |

25 |

Hydrogen |

22 |

1900*1200*1420 |

|

11 |

ZW-0.4/(9-10)-35 |

180 |

0.9-1 |

3.5 |

Hydrogen |

22 |

1900*1200*1420 |

|

12 |

ZW-0.8/(9-10)-25 |

400 |

0.9-1 |

2.5 |

Hydrogen |

30 |

1900*1200*1420 |

|

13 |

DW-2.5/0.5-17 |

200 |

0.05 |

1.7 |

Hydrogen |

30 |

2200*2100*1250 |

|

14 |

ZW-0.4/(22-25)-60 |

350 |

2.2-2.5 |

6 |

Hydrogen |

30 |

2000*1600*1200 |

|

15 |

DW-1.35/21-26 |

1500 |

2.1 |

2.6 |

Hydrogen |

30 |

2000*1600*1200 |

|

16 |

ZW-0.5/(25-31)-43.5 |

720 |

2.5-3.1 |

4.35 |

Hydrogen |

30 |

2200*2100*1250 |

|

17 |

DW-3.4/0.5-17 |

260 |

0.05 |

1.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

18 |

DW-1.0/7-25 |

400 |

0.7 |

2.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

19 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

37 |

2200*2100*1250 |

|

20 |

DW-1.7/5-15 |

510 |

0.5 |

1.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

21 |

DW-5.0/-7 |

260 |

Normal pressure |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

22 |

DW-3.8/1-7 |

360 |

0.1 |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

23 |

DW-6.5/8 |

330 |

Normal pressure |

0.8 |

Hydrogen |

45 |

2500*2100*1400 |

|

24 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

45 |

2500*2100*1400 |

|

25 |

DW-8.4/6 |

500 |

Normal pressure |

0.6 |

Hydrogen |

55 |

2500*2100*1400 |

|

26 |

DW-0.7/(20-23)-60 |

840 |

2-2.3 |

6 |

Hydrogen |

55 |

2500*2100*1400 |

|

27 |

DW-1.8/47-57 |

4380 |

4.7 |

5.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

28 |

VW-5.8/0.7-15 |

510 |

0.07 |

1.5 |

Hydrogen |

75 |

2500*2100*1400 |

|

29 |

DW-10/7 |

510 |

Normal pressure |

0.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

30 |

VW-4.9/2-20 |

750 |

0.2 |

2 |

Hydrogen |

90 |

2800*2100*1400 |

|

31 |

DW-1.8/15-40 |

1500 |

1.5 |

4 |

Hydrogen |

90 |

2800*2100*1400 |

|

32 |

DW-5/25-30 |

7000 |

2.5 |

3 |

Hydrogen |

90 |

2800*2100*1400 |

|

33 |

DW-0.9/20-80 |

1000 |

2 |

8 |

Hydrogen |

90 |

2800*2100*1400 |

|

34 |

DW-25/3.5-4.5 |

5700 |

0.35 |

0.45 |

Hydrogen |

90 |

2800*2100*1400 |

|

35 |

DW-1.5/(8-12)-50 |

800 |

0.8-1.2 |

5 |

Hydrogen |

90 |

2800*2100*1400 |

|

36 |

DW-15/7 |

780 |

Normal pressure |

0.7 |

Hydrogen |

90 |

2800*2100*1400 |

|

37 |

DW-5.5/2-20 |

840 |

0.2 |

2 |

Hydrogen |

110 |

3400*2200*1300 |

|

38 |

DW-11/0.5-13 |

840 |

0.05 |

1.3 |

Hydrogen |

110 |

3400*2200*1300 |

|

39 |

DW-14.5/0.04-20 |

780 |

0.004 |

2 |

Hydrogen |

132 |

4300*2900*1700 |

|

40 |

DW-2.5/10-40 |

1400 |

1 |

4 |

Hydrogen |

132 |

4200*2900*1700 |

|

41 |

DW-16/0.8-8 |

2460 |

0.08 |

0.8 |

Hydrogen |

160 |

4800*3100*1800 |

|

42 |

DW-1.3/20-150 |

1400 |

2 |

15 |

Hydrogen |

185 |

5000*3100*1800 |

|

43 |

DW-16/2-20 |

1500 |

0.2 |

2 |

Hydrogen |

28 |

6500*3600*1800 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1. Flow rate: ___Nm3/h

2. Gas component(mol%):

3. Inlet pressure: __bar(g)

4. Inlet temperature: ___℃

5. Outlet pressure: ___bar(g)

6. Outlet temperature: ___℃

7. Installation location: indoor or outdoor?

8. Location ambient temperature: ___℃

9. Power supply: __V/__ Hz/__ Ph?

10. Cooling method for gas: air cooling or water cooling? Is there cooling water of 28-32℃& 3-4 bar(g) on site?

11. Electrical classification: hazard or non-hazard?