GL series diaphragm compressor

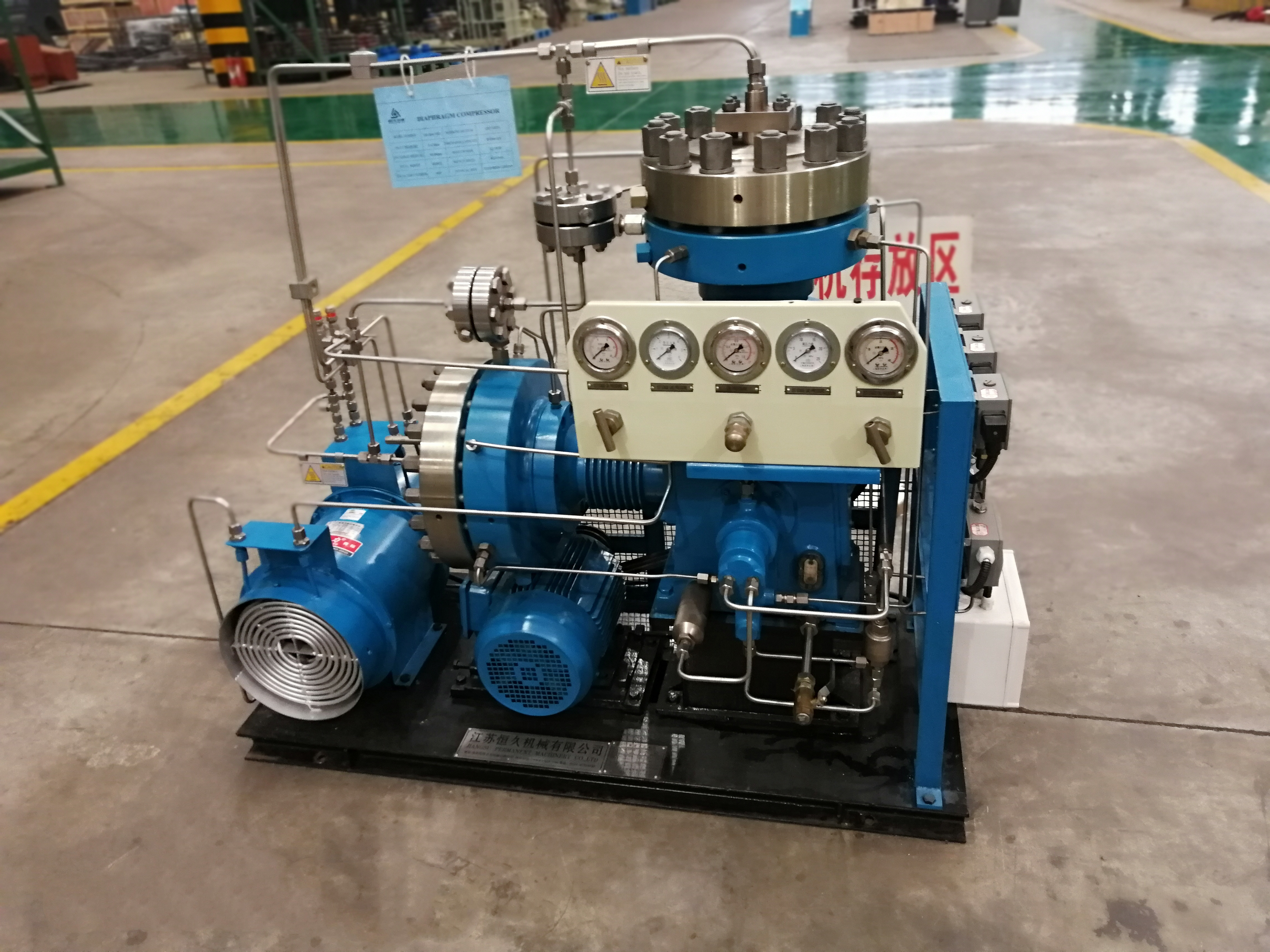

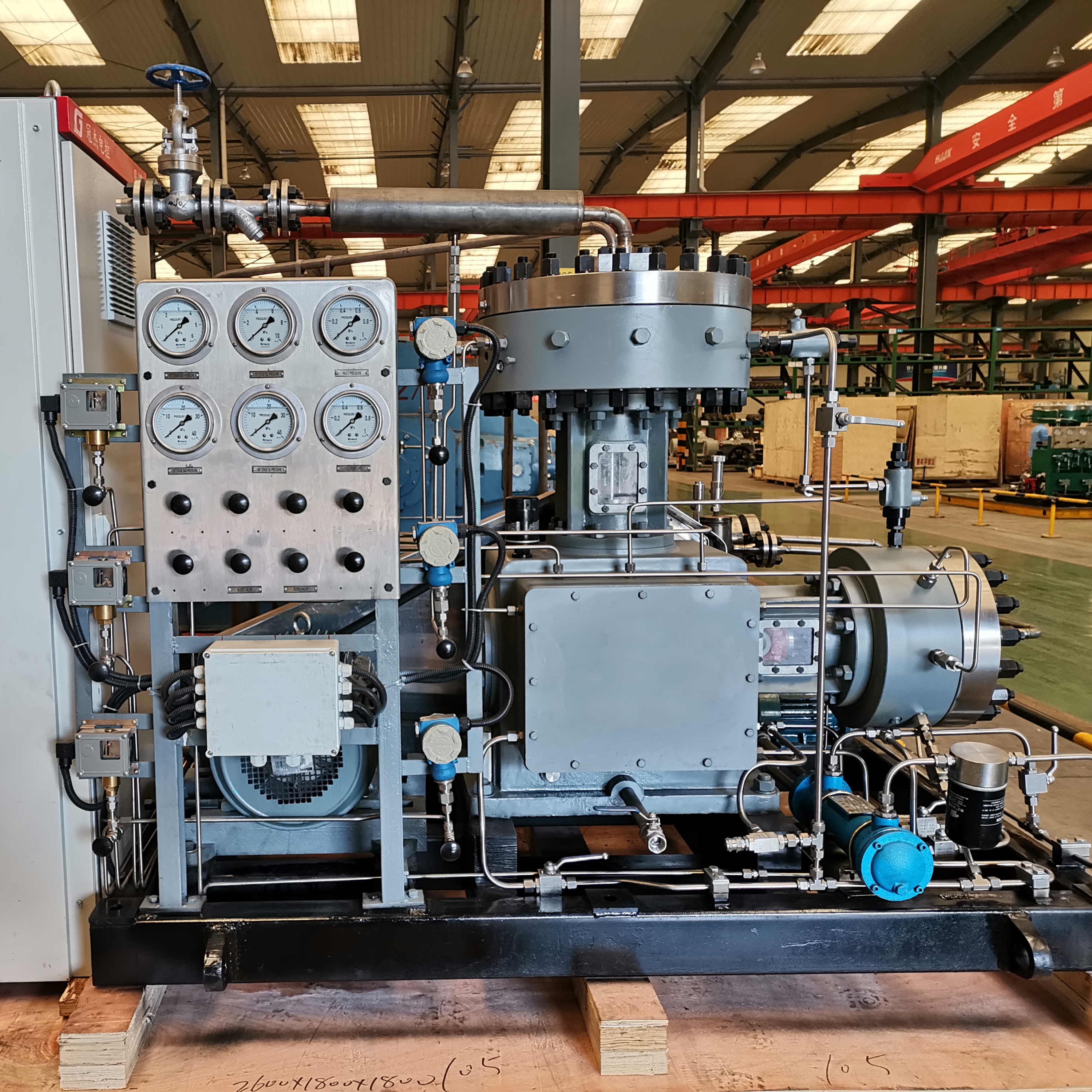

GL SERIES DIAPHRAGM COMPRESSOR-REFERENCE PICTURE

The Diaphragm Compressor is a positive displacement compressor with a special structure. It is the highest level compression method in the gas compression field. This compression method has no secondary pollution and has very good protection for the compressed gas. It has a large compression ratio, has good sealing performance, and the compressed gas is not polluted by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high-purity, rare and precious, flammable, explosive, toxic and harmful, corrosive, and high-pressure gases. This compression method is usually designated internationally to compress high-purity gases, flammable and explosive gases, toxic gases, and oxygen. and many more.

A. Classified by structure:

Diaphragm compressors have four main types: Z, V, D, L, etc.;

B. Classified by diaphragm material:

Diaphragm materials of diaphragm compressors are metal diaphragm (including black metal and non-ferrous metal) and non-metal diaphragms;

C. Classified by compressed media:

It can compress rare and precious gases, flammable and explosive gases, high-purity gases, corrosive gases, etc.

D. Classified by sports organization:

Crankshaft connecting rod, crank slider, etc.;

E. Classified by cooling method:

Water cooling, oil cooling, rear air cooling, natural cooling, etc.;

F. Classified by lubrication method:

Pressure lubrication, splash lubrication, external forced lubrication, etc.

GL series diaphragm compressor :

Structure type : L type

Piston Travel : 110-180mm

Max Piston force : 20KN-90KN

Max discharge Pressure : 100MPa

Flow Rate Range :10-1000Nm3/h

Motor Power : 7.5KW-90KW

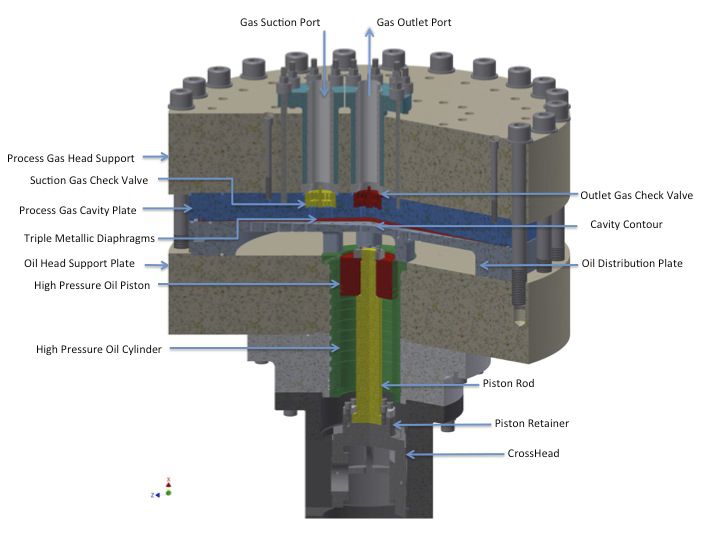

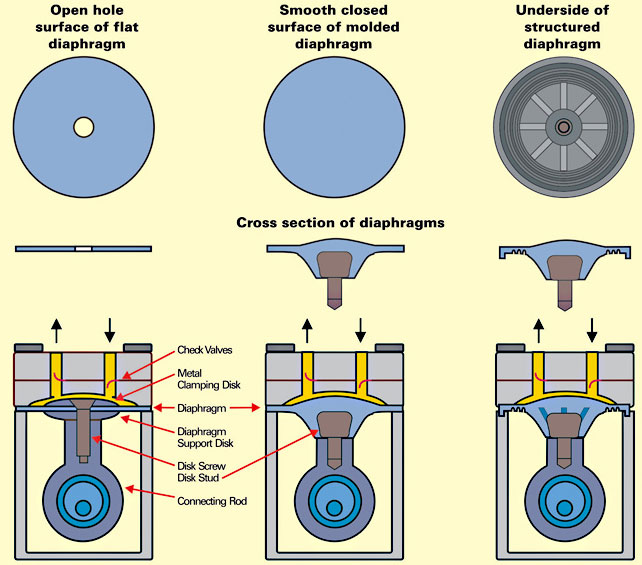

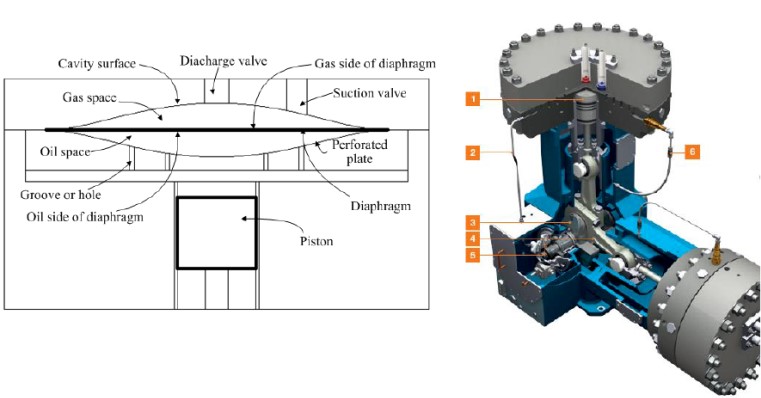

The compressor is consists of a three pieces of diaphragms. The diaphragm is clamped along the surrounding area by the hydraulic oil side and the process gas side of the process. The diaphragm is driven by the hydraulic driver in the film head to achieve the compression and transportation of the gas. The main body of the diaphragm compressor consists of two systems: the hydraulic oil system and the gas compression system, and the metal membrane separates these two systems.

Basically, the structure of the diaphragm compressor is divided into two parts: the hydraulic framework and the pneumatic force framework. During the compression process, there are two steps: the suction stroke and the delivery stroke.

GL SERIES DIAPHRAGM COMPRESSOR-PARAMETER TABLE

| GL series diaphragm compressor parameter table | ||||||||

| Model | Cooling water (L/h) | Flow (Nm³/h) |

Inlet pressure (MPa) |

Outlet pressure (MPa) |

Dimensions L×W×H(mm) | Weight (kg) | Motor Power (kW) | |

| 1 | GL-10/160 | 1000 | 10 | Atmospheric | 16 | 2200×1200×1300 | 1600 | 7.5 |

| 2 | GL-25/15 | 1000 | 25 | Atmospheric | 1.5 | 2200×1200×1300 | 1600 | 7.5 |

| 3 | GL-20/12-160 | 1000 | 20 | 1.2 | 16 | 2200×1200×1300 | 1600 | 7.5 |

| 4 | GL-70/5-35 | 1500 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1600 | 15 |

| 5 | GL-20/10-150 | 1500 | 20 | 1.0 | 15 | 2200×1200×1300 | 1600 | 15 |

| 6 | GL-25/5-150 | 1500 | 25 | 0.5 | 15 | 2200×1200×1300 | 1600 | 15 |

| 7 | GL-45/5-150 | 2000 | 45 | 0.5 | 15 | 2600×1300×1300 | 1900 | 18.5 |

| 8 | GL-30/10-150 | 1500 | 30 | 1.0 | 15 | 2300×1300×1300 | 1700 | 11 |

| 9 | GL-30/5-160 | 2000 | 30 | 0.5 | 16 | 2800×1300×1200 | 2000 | 18.5 |

| 10 | GL-80/0.05-4 | 4500 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4500 | 37 |

| 11 | GL-110/5-25 | 1400 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3600 | 22 |

| 12 | GL-150/0.3-5 | 1100 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4200 | 18.5 |

| 13 | GL-110/10-200 | 2100 | 110 | 1 | 20 | 2900×2000×1700 | 4000 | 30 |

| 14 | GL-170/2.5-18 | 1600 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4000 | 22 |

| 15 | GL-400/20-50 | 2200 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4500 | 30 |

| 16 | GL-40/100 | 3000 | 40 | 0.0 | 10 | 3700×1750×2000 | 3800 | 30 |

| 17 | GL-900/300-500 | 3000 | 900 | 30 | 50 | 3500×2350×2300 | 3500 | 55 |

| 18 | GL-100/3-200 | 3500 | 100 | 0.3 | 20 | 3700×1750×2150 | 5200 | 55 |

| 19 | GL-48/140 | 3000 | 48 | 0.0 | 14 | 3800×1750×2100 | 5700 | 37 |

| 20 | GL-200/6-60 | 3000 | 200 | 0.6 | 6.0 | 3800×1750×2100 | 5000 | 45 |

| 21 | GL-140/6-200 | 5000 | 140 | 0.6 | 20.0 | 3500×1380×2350 | 4500 | 55 |

| 22 | GL-900/10-15 | 2500 | 900 | 1.0 | 1.5 | 3670×2100×2300 | 6500 | 37 |

| 23 | GL-770/6-20 | 4500 | 770 | 0.6 | 2.0 | 4200×2100×2400 | 7600 | 55 |

| 24 | GL-90/4-220 | 6000 | 90 | 0.4 | 22.0 | 3500×2100×2400 | 7000 | 45 |

| 25 | GL-1900/21-30 | 3800 | 1800 | 2.1 | 3.0 | 3700×2000×2400 | 7000 | 55 |

| 26 | GL-300/20-200 | 4200 | 300 | 2.0 | 20.0 | 3670×2100×2300 | 6500 | 45 |

| 27 | GL-200/15-200 | 4000 | 200 | 1.5 | 20.0 | 3500×2100×2300 | 6000 | 45 |

| 28 | GL-330/8-30 | 5000 | 330 | 0.8 | 3.0 | 3570×1600×2200 | 4000 | 45 |

| 29 | GL-150/6-200 | 5000 | 150 | 0.6 | 20.0 | 3500×1600×2100 | 3800 | 55 |

| 30 | GL-300/6-25 | 4500 | 300 | 0.6 | 2.5 | 3450×1600×2100 | 4000 | 45 |