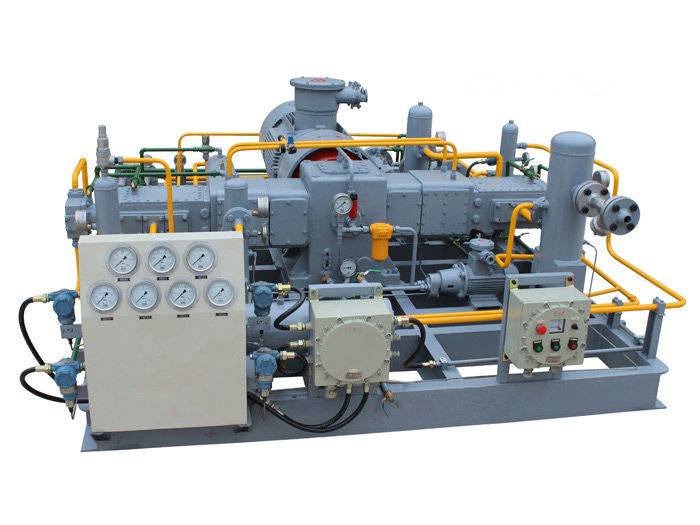

Oir Free Industrial CNG Natural Gas Compressor

NATURAL COMPRESSOR-REFERENCE PICTURE

A piston compressor is a kind of piston reciprocating motion to make gas pressurization and a gas delivery compressor mainly consists of a working chamber, transmission parts, body, and auxiliary parts. The working chamber is directly used to compress the gas, the piston is driven by the piston rod in the cylinder for reciprocating motion, The volume of the working chamber on both sides of the piston changes in turn, and the volume decreases on one side of the gas due to the pressure increase through the valve discharge, the volume increases on one side due to the reduction of air pressure through the valve to absorb the gas.

We have various gas compressors, such as Hydrogen compressors, Nitrogen compressors, Natural gas compressors, Biogas compressors, Ammonia compressors, LPG compressors, CNG compressors, Mix gas compressors, and so on.

Product Description

Natural gas compressor

This series of compressor units is mainly used in the pressurized transmission of pipeline natural gas, oil and gas processing plants, and other occasions.

Features

1. Reliable operation and easy maintenance.

2. Flexible load adjustment, a wide range of air intake, and a wide range of adaptations.

3, the overall skid-mounted structure, low noise, easy to install in urban areas, saving investment.

4. Siemens PLC control system with a high degree of automation and convenient remote control.

Advantages of Gas Compressor:

1. High-quality material, Stable and reliable operation

2. Low Maintenance cost and low noise

3. Easy to install on-site and connect with the user's pipeline system to operate

4. Alarm automatic shutdown to protect machine function

5. High pressure and flow

Lubrication includes Oil lubrication and oil-free lubrication;

The cooling method includes Water cooling and air cooling

Installation type includes Stationary, Mobile, and Skid Mounting.

Type includes: V-type, W-type, D-type, Z-type

Technical parameters and specifications

|

No |

Model |

Gas flow (Nm3/h) |

Inlet pressure (Mpa) |

Outlet pressure (Mpa) |

Power (kw) |

Dimensions (mm) |

|

1 |

ZW-0.4/ 2-250 |

60 |

0.2 |

25 |

18.5 |

2800*2200*1600 |

|

2 |

ZW-0.81/ (1~3)-25 |

120 |

0.1~0.3 |

2.5 |

22 |

1000*580*870 |

|

3 |

DW-5.8/0.5-5 |

400~500 |

0.05 |

0.5 |

37 |

2000*1600*1200 |

|

4 |

DW-10/2 |

510 |

Atmospheric pressure |

0.2 |

37 |

2000*1600*1200 |

|

5 |

DW-6.0/5 |

300 |

Atmospheric pressure |

0.5 |

37 |

2000*1600*1200 |

|

6 |

DW-0.21/(20~30)-250 |

270 |

2~3 |

25 |

45 |

3200*2200*1600 |

|

7 |

ZW-0.16/60-250 |

480 |

6 |

25 |

45 |

3000*2200*1600 |

|

8 |

ZW-0.46 /(5~10)-250 |

200 |

0.5~1.0 |

25 |

45 |

3000*2200*1600 |

|

9 |

DW-1.34/2-250 |

208 |

0.2 |

25 |

55 |

3400*2200*1600 |

|

10 |

DW-0.6/24-85 |

720 |

2.4 |

8.5 |

55 |

2200*1600*1200 |

|

11 |

ZW-2.9/14.2-20 |

220 |

1.42 |

2 |

55 |

2200*1600*1200 |

|

12 |

VW-2.0/(2~4)-25 |

410 |

0.2~0.4 |

2.5 |

55 |

3400*2200*1600 |

|

13 |

DW-0.85/(3~4)-250 |

180 |

0.3~0.4 |

25 |

55 |

2400*1800*1500 |

|

14 |

DW-25-(0.2~0.3)-1.5 |

1620 |

0.02~0.03 |

0.15 |

75 |

2400*1800*1500 |

|

15 |

VW-8.0/0.3-25 |

540 |

0.03 |

2.5 |

90 |

2400*1800*1500 |

|

16 |

DW-6.8/0.05-40 |

200~400 |

0.005 |

4 |

90 |

2400*1800*1500 |

|

17 |

DW-1.2 /6-250 |

420 |

0.6 |

25 |

90 |

3400*2200*1600 |

|

18 |

DW-3.45/3.5-28 |

800 |

0.35 |

2.8 |

90 |

2400*1800*1500 |

|

19 |

DW-8.3/0.6-15 |

660 |

0.06 |

15 |

90 |

2400*1800*1500 |

|

20 |

DW-0.48/40-250 |

900 |

4 |

25 |

110 |

3400*2200*1600 |

|

21 |

DW-2.7/2-200 |

420 |

0.2 |

20 |

110 |

3400*2200*1600 |

|

22 |

VW-3.22/2-250 |

500 |

0.2 |

25 |

132 |

3400*2200*1600 |

|

23 |

DW-6.0/(1~3)-25 |

840 |

0.1~0.3 |

2.5 |

132 |

3400*2200*1300 |

|

24 |

DW-0.92/16-220 |

800 |

1.6 |

22 |

132 |

3400*2200*1600 |

|

25 |

VW-3.5/2.5-250 |

600 |

0.25 |

25 |

160 |

4000*2000*1600 |

|

26 |

DW-6.7/2-25 |

1020 |

0.2 |

2.5 |

160 |

4000*2000*1300 |

|

27 |

DW-3.0/3-250 |

500 |

0.3 |

25 |

160 |

4800*2200*1600 |

|

28 |

DW-30.50/0.05-4.3 |

1620 |

0.005 |

0.43 |

160 |

4800*2200*1300 |

|

29 |

DW-1.1/10-250 |

600 |

1 |

25 |

160 |

4800*2200*1600 |

|

30 |

DW-3.35/(2~3)-250 |

600 |

0.2~0.3 |

25 |

160 |

4800*2200*1600 |

|

31 |

DW-7.7/0.5-150 |

600 |

0.05 |

15 |

160 |

4800*2200*1600 |

|

32 |

VW-2.6/5-250 |

800 |

0.5 |

25 |

185 |

4800*3900*1850 |

|

33 |

DW-0.9/40-250 |

1860 |

4 |

25 |

220 |

5500*3900*1700 |

|

34 |

DW-19.35/(4~6)-12 |

6000 |

0.4~0.6 |

1.2 |

280 |

5500*3900*1700 |

|

35 |

DW-34/1.04-8.5 |

3540 |

0.104 |

0.85 |

315 |

6500*4000*1800 |

|

36 |

DW-7.5/30-48 |

17400 |

3 |

4.8 |

350 |

6800*4000*1800 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com