Recently, our company has made a significant breakthrough in ultra-high-pressure equipment R&D—the 220MPa ultra-high-pressure hydraulic-driven compressor, independently developed and manufactured by our technical team, has been officially delivered to a client. This landmark accomplishment not only sets a new pressure record in our company’s history but also reinforces our technological prowess, marking a transformative leap in the research, development, and application of ultra-high-pressure technologies.

In September 2024, an industrial client approached us via our official website with a highly demanding technical request: the customization of a hydraulic-driven compressor with a maximum discharge pressure of 220MPa for industrial sealing integrity testing. Through discussions, we learned that this specification represented an unprecedented challenge in the domestic market, where the highest pressure level previously achieved in practical applications was 90MPa. Confronting this challenge head-on, our technical team promptly conducted multi-phase feasibility analyses and, leveraging decades of industry expertise, committed to delivering the project.

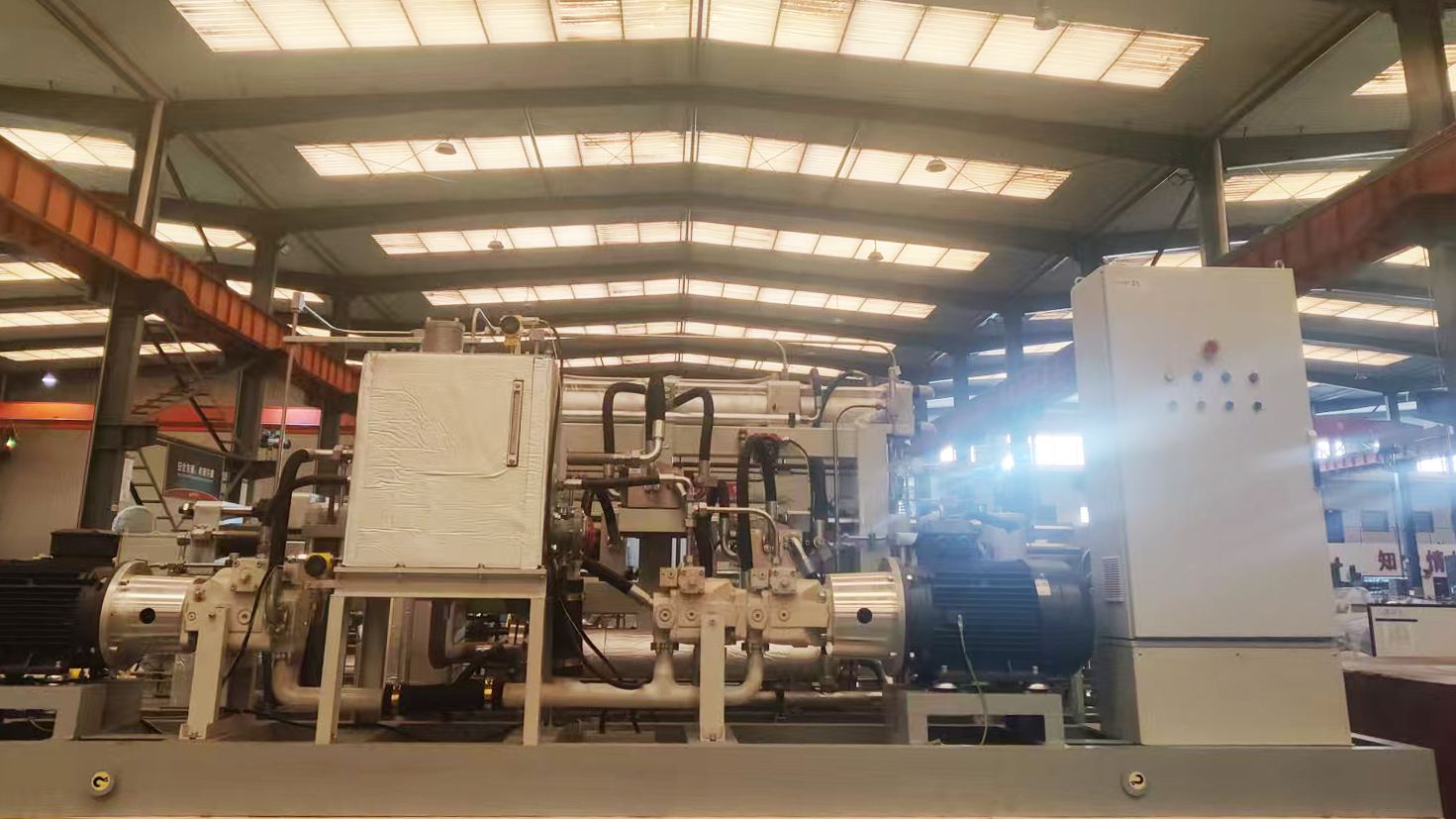

Upon project initiation, our team launched an intensive technical(R&D initiative). From conceptual design to prototype development, we resolved critical challenges including sealing failure under ultra-high-pressure conditions, material deformation, and thermodynamic instability. After nearly five months of relentless optimization, the engineering prototype was successfully completed. The prototype then underwent rigorous testing for one month under both laboratory and real-world operating conditions, with all performance metrics meeting or surpassing client specifications. Following on-site validation and acceptance by the client’s expert team, the compressor was formally delivered in March 2025.

The compressor features high system integration, an exceptional compression ratio, and energy-efficient operation, achieving a maximum discharge pressure of 220MPa. Under specified operating conditions (Pi=15.0MPa, Po=207MPa), it delivers a discharge capacity of ≥220Nm³/h, fully complying with the client’s stringent requirements. Its superior performance and reliability not only ensure robust support for industrial sealing tests but also establish a new industry benchmark for ultra-high-pressure applications.

The successful delivery of this 220MPa ultra-high-pressure hydraulic-driven compressor stands as a resounding validation of our R&D capabilities and signifies a monumental advancement in China’s ultra-high-pressure equipment manufacturing standards. This achievement will provide critical technical support for industrial sealing tests, ultra-high-pressure material research, and related fields, while driving independent innovation in China’s high-end equipment manufacturing sector.

Moving forward, our company will continue to deepen expertise in ultra-high-pressure technologies, prioritize client-centric innovation, and accelerate technological breakthroughs and product upgrades. We remain dedicated to delivering efficient, reliable solutions across industries, empowering “Made in China” to ascend as a global leader in high-end markets.

Post time: Apr-17-2025