Diaphragm compressor as a special compressor, its working principle and structure is huge different from other types of compressor. There will be some unique failures. So, some customers who are not very familiar with the diaphragm compressor will worry that if there is a failure, what should I do?

This article, mainly introduces, diaphragm compressor in the daily operation process, there will be some common failures, and solutions. Know it, you will be free of worries.

1. The cylinder oil pressure is too low, but the gas discharge pressure is normal

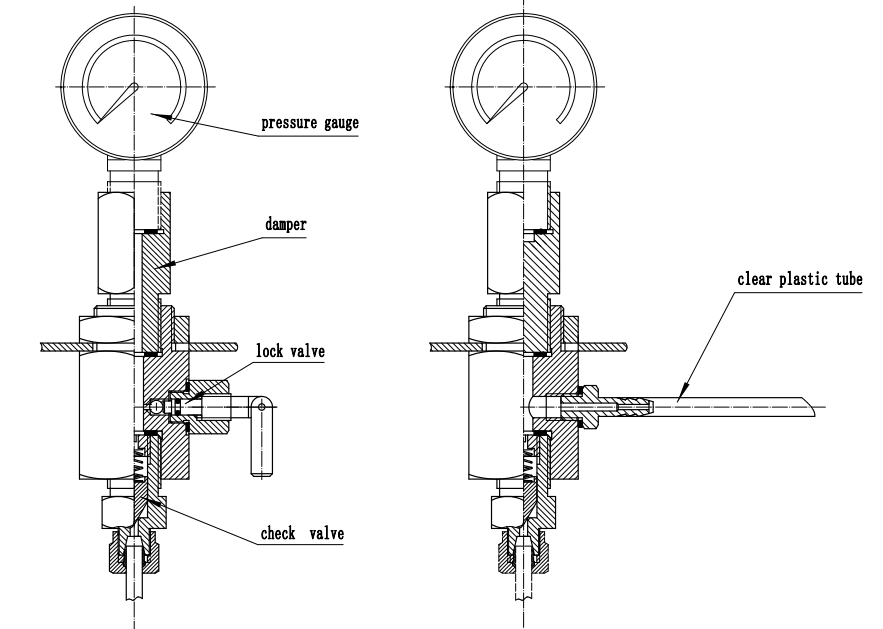

1.1 Pressure gauge is damaged or damper(under gauge) is blocked. Cannot display pressure properly, need to replace the oil pressure gauge or damper.

1.2 The lock valve is not tightly closed. Tighten the handle of the lock valve and check whether the oil is drained from clear plastic tube. If oil still drain, replace the lock valve.

1.3 Check and clean the check valve under pressure gauge. If damaged, replace it.

2. The cylinder oil pressure is too low, and gas discharge pressure is also too low.

2.1 Crankcase oil level is too low. The oil level should be kept between the upper and lower scale lines.

2.2 There is gas residual air mixed in the oil. Turn the lock valve handle counterclockwise and watch the clear plastic tube until no foam is flowing.

2.3 The check valves which fixed on oil cylinder and under oil pressure gauge are not tightly sealed. Repair or replace them.

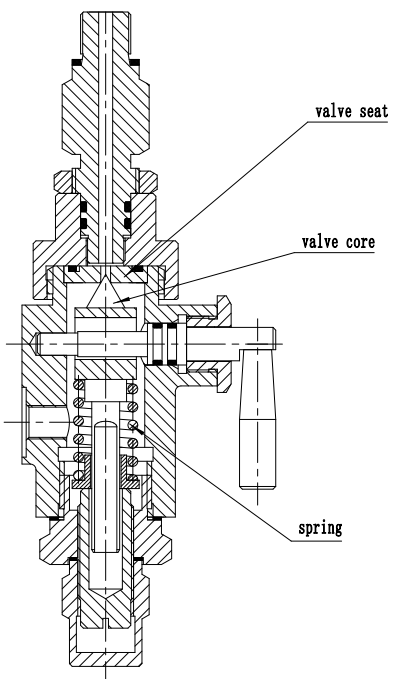

2.4 Oil overflow valve works abnormally. Valve seat, valve core or spring failure. The faulty parts should be repaired or replaced;

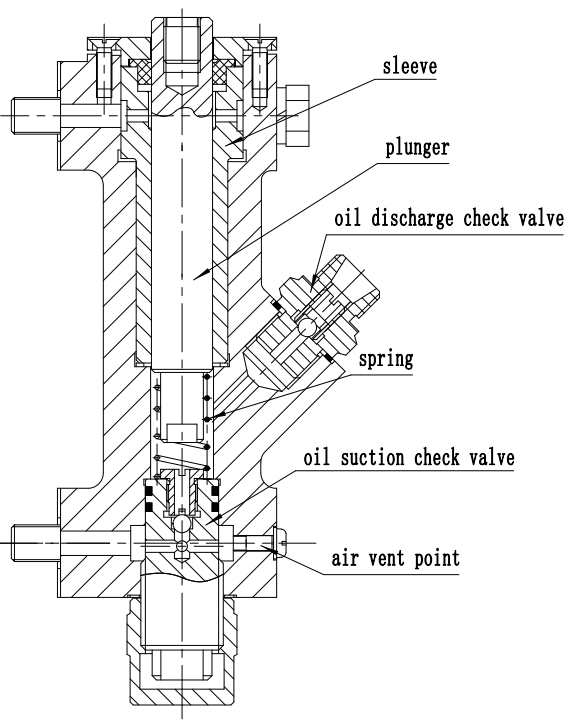

2.5 Oil pump works abnormally. When the oil pump is working normally, pulse vibration can be felt on oil tube. If not, firstly check(1) whether there is residual gas in the pump via loosing the air vent point screw. (2) remove the bearing end cover and check whether the plunger is stuck. If yes, remove and clean it until the plunger rod can move freely(3) If there is no oil discharge or oil discharge but no pressure, check and clean the oil suction and discharge check valves(4). check the clearance between the plunger with sleeve, if the gap is too much, replace them.

2.6 check the clearance between the piston ring with cylinder liner, if the gap is too much, replace them.

3. The discharge temperature is too high

3.1 Pressure ratio is too large (low suction pressure and high discharge pressure);

3.2 The cooling effect is not good; Check the cooling water flow and temperature, whether the cooling channel is blocked or seriously scaled, and clean or dredge the cooling channel.

4. Insufficient of gas flow rate

4.1 The suction pressure is too low or the inlet filter is blocked. Clean the intake filter or adjust the suction pressure;

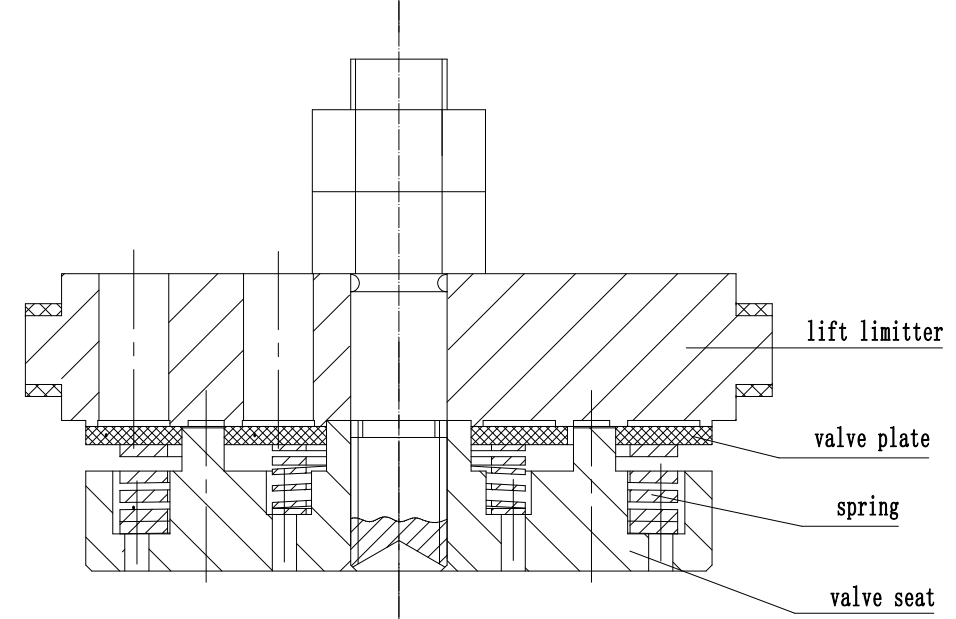

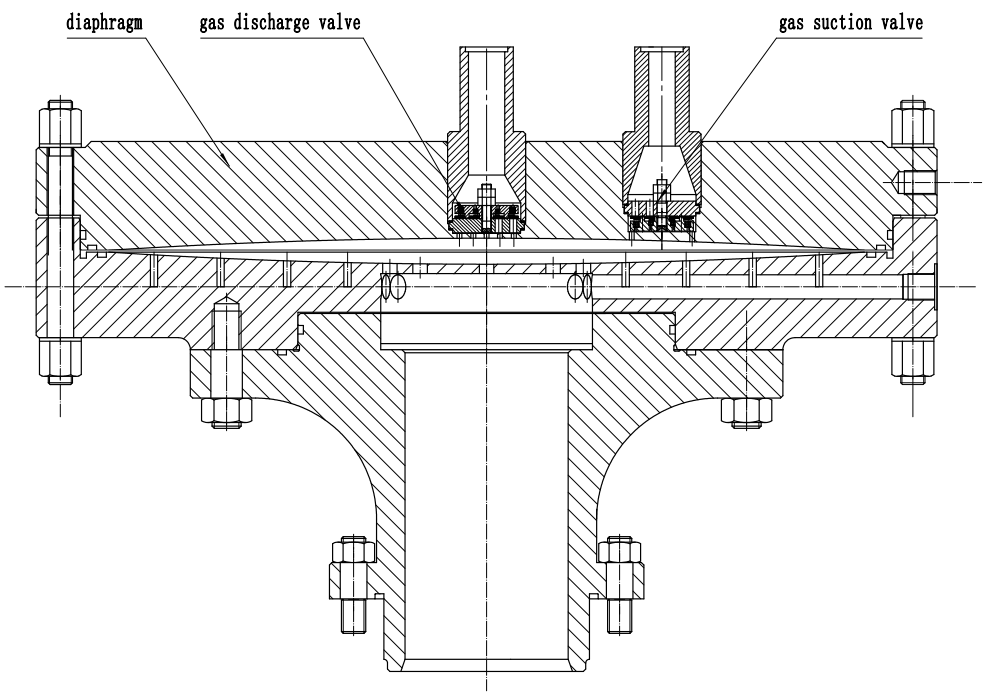

4.2 Check the gas suction valve and discharge. If dirty, clean them, if damaged, replace them.

4.3 Check the diaphragms, if there is serious deformation or damage,replace them.

4.4 Cylinder oil pressure is low, Adjust the oil pressure to the required value.

Post time: Nov-14-2022