In recent years, hydrogen energy has re-emerged as a critical topic in the new energy sector. The hydrogen industry has been explicitly listed as one of the key frontier emerging industries for development, alongside sectors such as new materials and innovative pharmaceuticals. Reports emphasize the need to actively cultivate new growth engines, including bio-manufacturing, commercial aerospace, and low-altitude economy, while explicitly prioritizing the acceleration of hydrogen industry development for the first time. This underscores the vast potential of hydrogen energy.

Currently, coal-based hydrogen production dominates the supply structure, accounting for 64%, followed by industrial by-product hydrogen (21%), natural gas-based hydrogen (14%), and other methods (1%). This reveals that fossil fuel-based hydrogen production holds an absolute dominance at 99%, while electrolysis-based “green hydrogen” and other methods remain marginal. Consequently, current hydrogen refueling stations primarily adopt the following production-storage-transportation model: Petrochemical companies in remote areas produce hydrogen from fossil fuels, compress low-pressure hydrogen (typically ~1.5MPa) to ~20MPa using compressors, and store it in 22MPa tube trailers. The hydrogen is then transported to refueling stations, where it undergoes secondary compression to 45MPa for fuel cell vehicles. This spatially fragmented model increases transportation costs, equipment expenses, and time consumption, while remaining constrained by fossil fuel-dependent “gray hydrogen” production.

Furthermore, under current regulations, hydrogen is classified as a flammable and explosive hazardous chemical. As a result, hydrogen production projects are predominantly concentrated in remote chemical parks with stringent safety and environmental requirements.

With advancing electrolysis technology, the production cost of green hydrogen is gradually decreasing. Simultaneously, environmental policies such as “carbon peaking and carbon neutrality” are driving green hydrogen to become a crucial direction for future gaseous energy development. The International Energy Agency predicts that by 2030, low-carbon hydrogen technologies like electrolysis will account for 14% of the hydrogen market, significantly influencing refueling station layouts. Electrolysis-based production, with its simple and accessible feedstock, enables hydrogen production beyond traditional chemical parks. Direct compression of on-site produced hydrogen for vehicle refueling eliminates long-distance transportation and secondary compression, effectively reducing economic and time costs.

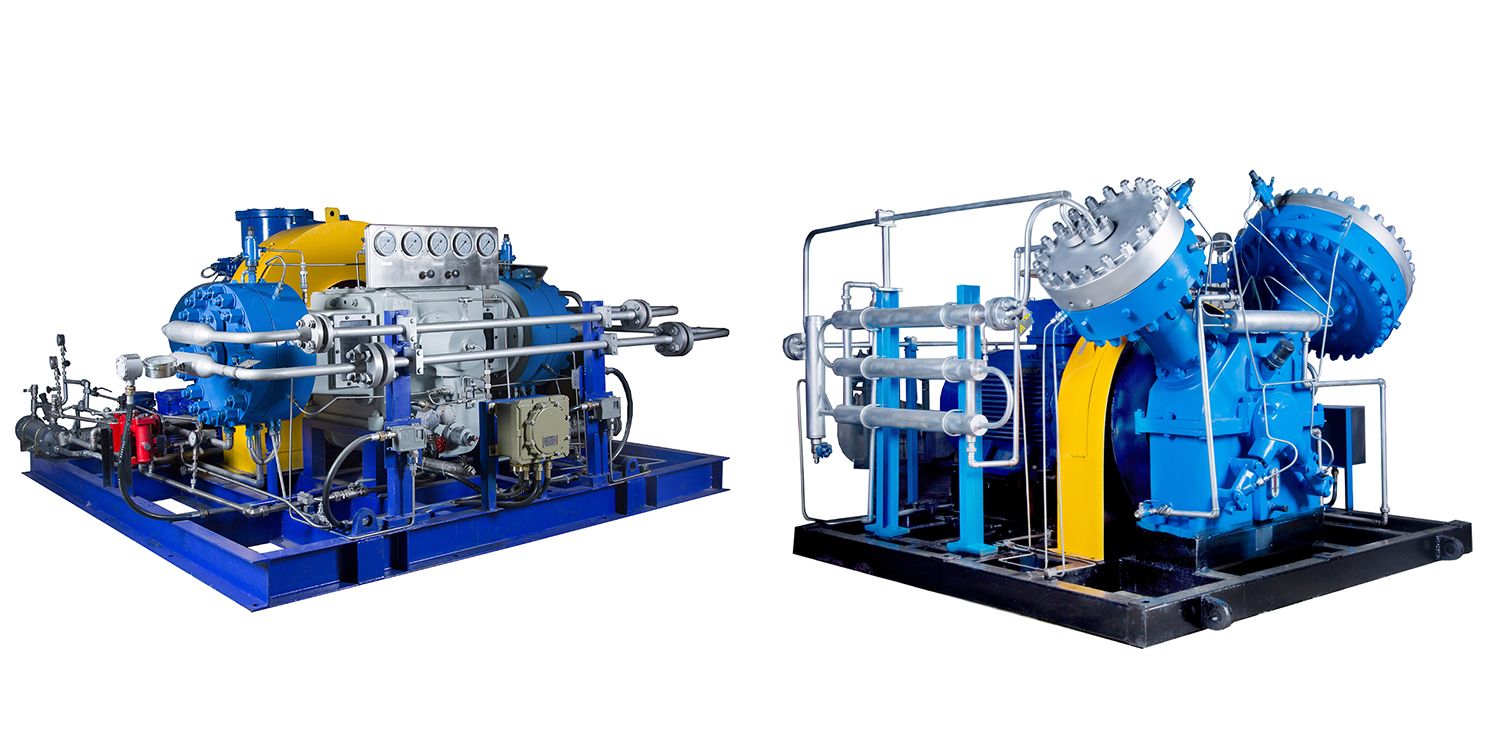

To adapt to the mainstream fossil fuel-based hydrogen supply chain, two types of diaphragm compressors currently dominate the market: 1) Hydrogen filling units with ~1.5MPa intake pressure and 20-22MPa discharge pressure; 2) Refueling station compressors with 5-20MPa intake pressure and 45MPa discharge pressure. However, this two-stage process requires coordinated operation of both units. Moreover, when hydrogen storage cylinder pressure drops below 5MPa, the refueling compressors become inoperable, resulting in low hydrogen utilization rates.

In contrast, integrated hydrogen production-refueling stations demonstrate superior efficiency. In this model, hydrogen from electrolysis can be directly compressed from ~1.5MPa to 45MPa using a single diaphragm compressor, significantly reducing equipment and time costs. The lower intake pressure threshold (1.5MPa vs. 5MPa) also substantially improves hydrogen utilization.

As electrolysis technology advances, integrated hydrogen stations are expected to gain wider adoption, driving market demand for 1.5MPa-to-45MPa diaphragm compressors. Our company possesses comprehensive design and manufacturing capabilities to provide customized solutions for this application scenario. With the growing proportion of green hydrogen production, integrated stations are projected to proliferate, expanding both the application prospects of diaphragm compressors and our product portfolio while delivering innovative refueling solutions.

Nevertheless, challenges persist in developing integrated hydrogen stations and associated compressors, including high electrolysis costs, hydrogen’s hazardous chemical classification, and incomplete hydrogen infrastructure. Effectively addressing these issues will be crucial to advancing integrated hydrogen energy systems.

Post time: Feb-27-2025