In the operation of hydrogen refueling stations, the compressor is one of the key equipment, and its service life is a complex issue affected by multiple factors.

Generally speaking, the service life of hydrogen refueling station compressors is between 10 and 20 years, but this is only a rough range. The actual service life may vary due to various factors.

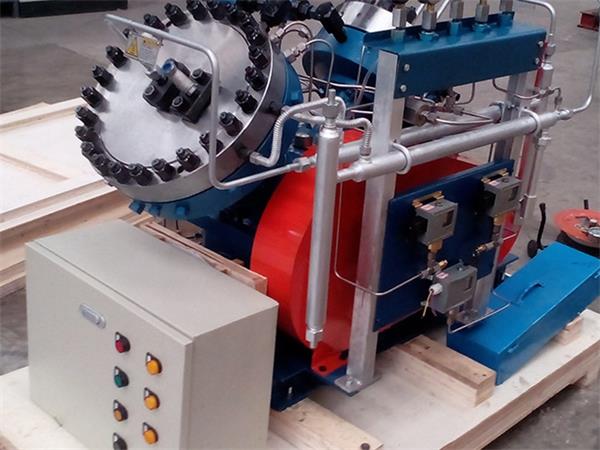

Firstly, the quality and manufacturing process of the compressor are the fundamental factors that affect its lifespan. Excellent material selection, precise machining and manufacturing, and strict quality inspection can ensure that the compressor has good performance and reliability in the initial stage, laying a solid foundation for long-term stable operation. Compressors that adopt advanced design concepts and manufacturing technologies are often able to better cope with various challenges during operation, thereby extending their service life.

The operating environment has a significant impact on the lifespan of the compressor. The geographical location, climatic conditions, and working environment temperature and humidity inside the hydrogen refueling station will all have an impact on the compressor. For example, operating in high temperature, high humidity, or dusty environments can accelerate the wear and corrosion of compressor components, shortening their service life.

The frequency of use and load situation of the compressor are also important considerations. If the business of the hydrogen refueling station is busy, the compressor needs to be frequently started and operated at high load for a long time, which will increase equipment loss and shorten its service life. On the contrary, reasonable usage arrangements and appropriate shutdown maintenance can provide sufficient rest and adjustment for the compressor, which helps to extend its lifespan.

The level of maintenance is directly related to the service life of the compressor. Regular maintenance work such as inspection, cleaning, lubrication, component replacement, and troubleshooting can promptly identify and solve potential problems, prevent small problems from escalating into major ones, and thus extend the normal operation time of the compressor. Following the manufacturer’s recommendations for standardized maintenance is key to ensuring the long-term stable operation of the compressor.

The technical level and operational standards of the operators cannot be ignored. Skilled and professional operators are able to operate the compressor correctly, avoiding equipment damage caused by misoperation. Following the correct start-up and shutdown procedures, as well as accurately monitoring and adjusting parameters during operation, can help protect the compressor and extend its service life.

In addition, technological updates and upgrades will also have an impact on the service life of compressors. With the continuous advancement of technology, new materials, techniques, and designs may gradually make old models of compressors outdated, increase maintenance costs, and no longer have economic and performance advantages.

For example, a hydrogen refueling station has adopted high-quality compressors and provided them with a good operating environment and meticulous maintenance. The operators have undergone strict training and operated the compressor strictly according to the specifications, which has maintained good operating conditions for 15 years.

However, another hydrogen refueling station, due to its harsh environment, high frequency of use, and inadequate maintenance, resulted in serious compressor failures in just about 8 years and had to be replaced in advance.

In summary, the service life of hydrogen refueling station compressors is not a fixed number, but is influenced by various factors such as quality, operating environment, frequency of use, maintenance, and operational level. By selecting excellent products, optimizing the operating environment, using them reasonably, maintaining them carefully, and operating them in a standardized manner, the service life of the compressor can be extended to a greater extent, ensuring the safe, stable, and efficient operation of the hydrogen refueling station.

Post time: Sep-07-2024