OEM Diaphragm Compressor Manufacturers Suppliers – Chemical Process heavy duty Piston Compressor – Huayan

OEM Diaphragm Compressor Manufacturers Suppliers – Chemical Process heavy duty Piston Compressor – Huayan Detail:

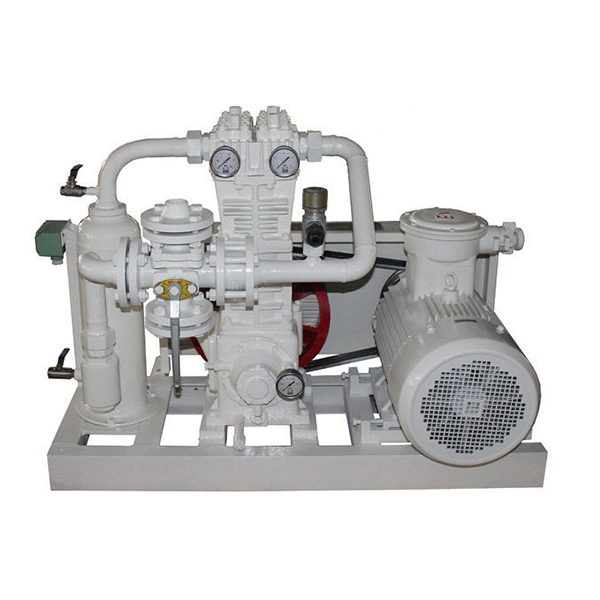

CHEMIACAL PROCESS COMPRESSOR-REFERENCE PICTURE

The gas compressor is suitable for a variety of gas pressurization, transportation and other working conditions. Suitable for medical, industrial, flammable and explosive, corrosive and toxic gases.

Chemical process compressors refer to process reciprocating piston compressors used to compress various single or mixed media gases in petroleum and chemical processes, as well as chemical exhaust gas recycling systems. Its main function is to transport the medium gas in the reaction device and provide the required pressure to the reaction device.

◎Designed for specific process flow.

◎The whole machine is skid-mounted and advanced in structure.

◎The middle body of the slideway and the cylinder can be designed in different structural forms according to the process requirements.

A. Classified by structure:

Piston compressors have four main types: Z, D, M, etc.;

B. Classified by compressed media:

It can compress rare and precious gases, flammable and explosive gases, etc.

C. Classified by sports organization:

Crankshaft connecting rod, crank slider, etc.;

D. Classified by cooling method:

Water cooling, oil cooling, rear air cooling, natural cooling, etc.;

E. Classified by lubrication method:

Pressure lubrication, splash lubrication, external forced lubrication, etc.

CHEMIACAL PROCESS COMPRESSOR-PARAMETER TABLE

|

Chemical Process Compressor Parameter Table |

|||||||

|

Mdoel |

Flow-rate (Nm3/h) |

Intake Pressure(Mpa) |

Exhaust Pressure (Mpa) |

Medium |

Rotor power (kw) |

Dimensions L×W×H(mm) |

|

|

1 |

DW-1.0/1.0 |

60 |

Normal |

0.1 |

Exhaust |

4 |

2200×1800×1100 |

|

2 |

ZW-0.15/(12-20)-(20-28) |

120 |

1.2-2 |

2-2.8 |

Acrylic |

5.5 |

1600×1100×1400 |

|

3 |

ZW-0.15/6.5-25 |

55 |

0.65 |

2.5 |

Nitrogen |

7.5 |

1600×1100×1400 |

|

4 |

ZW-0.85/(1.5-2)-4 |

120 |

0.15-0.2 |

0.4 |

Carbon dioxide |

7.5 |

1600×1100×1400 |

|

5 |

ZW-0.8/4-9 |

210 |

0.4 |

0.9 |

Low temperature ethylene |

7.5 |

1600×1100×1400 |

|

6 |

ZW-0.67/(3-4)-(8-10) |

150 |

0.3-0.4 |

0.8-1 |

Oxygen |

11 |

1600×1100×1400 |

|

7 |

ZW-0.8 /8-12 |

360 |

0.8 |

1.2 |

Vinyl chloride |

11 |

1600×1100×1400 |

|

8 |

ZW-0.8 /8-12 |

360 |

0.8 |

1.2 |

Lsobutene |

11 |

1600×1100×1400 |

|

9 |

ZW-2.0/0.5-(2-3) |

155 |

0.05 |

0.2-0.3 |

Hydrogen chloride |

11 |

1600×1100×1400 |

|

10 |

ZW-0.12/50-60 |

300 |

5 |

6 |

Syngas |

11 |

1600×1100×1400 |

|

11 |

ZW-1.5/7 |

75 |

Normal |

0.7 |

Coalgas |

11 |

1600×1100×1400 |

|

12 |

ZW-1.0/0.2-20 |

60 |

0.02 |

2 |

Dimethyl ether |

15 |

1500×1200×1400 |

|

13 |

ZW-0.95/8-12 |

420 |

0.8 |

1.2 |

Propane |

15 |

1500×1200×1400 |

|

14 |

DW-2.0/7 |

100 |

Normal |

0.7 |

Sulfur dioxide |

15 |

2200×1900×1300 |

|

15 |

ZW-2.84-2 |

150 |

Normal |

0.2 |

Carbon monoxide |

15 |

1600×1200×1500 |

|

16 |

ZW-1.7 /7 |

90 |

Normal |

0.7 |

Cracked gas |

15 |

1600×1200×1500 |

|

17 |

ZW-0.65/1.0-25 |

65 |

0.1 |

2.5 |

Ethylene |

15 |

1600×1200×1500 |

|

18 |

ZW-0.85/0.4-25 |

60 |

0.04 |

2.5 |

Cracked gas |

15 |

1600×1200×1500 |

|

19 |

VW-7.0/0.1-1.0 |

400 |

0.01 |

0.1 |

Hexane /propylene |

18.5 |

1600×1200×1500 |

|

20 |

DW-1.1/19-23 |

1100 |

1.9 |

2.3 |

Rich gas |

18.5 |

2300×1900×1300 |

|

21 |

ZW-2.0/(1-2.5_)-5.5 |

270 |

0.1-0.25 |

0.55 |

C3/C4 |

18.5 |

1700×1200×1600 |

|

22 |

ZW- 2.1/0.15-15 |

120 |

0.015 |

1.5 |

Hexafluoroethylene/Hexafluoropropylene |

22 |

1700×1200×1600 |

|

23 |

ZW-6.7/2.5 |

340 |

Normal |

0.25 |

Lsobutane |

22 |

1700×1200×1600 |

|

24 |

ZW-1.5/4 |

90 |

Normal |

0.4 |

Trifluoromethane |

22 |

1700×1200×1600 |

|

25 |

ZW-1.5/10-16 |

840 |

1 |

1.6 |

Butadiene |

22 |

1700×1200×1600 |

|

26 |

ZW-8.9/(0.2-0.4)-1.0 |

600 |

0.02-0.04 |

0.1 |

Coalgas |

22 |

1700×1200×1600 |

|

27 |

DW-3.0/8 |

150 |

Normal |

0.8 |

Mashgas |

22 |

2800×2200×1600 |

|

28 |

ZW-0.9/6-25 |

310 |

0.6 |

2.5 |

Nitrogen |

30 |

1800×1300×1600 |

|

29 |

ZW-0.88/10-20 |

500 |

1 |

2 |

Coalgas |

30 |

1800×1300×1600 |

|

30 |

ZW-1.1/1.0-31 |

100 |

0.1 |

3.1 |

Raw gas |

30 |

1800×1300×1600 |

|

31 |

ZW-1.0/7-20 |

400 |

0.7 |

2 |

Nitrogen |

30 |

1800×1300×1600 |

|

32 |

DW-3.0/20 |

150 |

Normal |

2 |

Freon |

30 |

2800×2500×1400 |

|

33 |

DW-3.0/1-8 |

300 |

0.1 |

0.8 |

Methyl chloride |

30 |

2800×2200×1400 |

|

34 |

DW-3.0/(0.2-1)-10 |

240 |

0.02-0.1 |

1 |

Boil off Gas |

30 |

2800×2200×1400 |

|

35 |

ZW-0.63/3-200 |

130 |

0.3 |

20 |

Nitrogen |

37 |

3200×2300×1600 |

|

36 |

DW-1.4/2-35 |

210 |

0.2 |

3.5 |

Mixed gas |

37 |

2800×2200×1400 |

|

37 |

ZW-8.1/(0.03-0.1)-2.5 |

450 |

0.003-0.01 |

0.25 |

Coalgas |

37 |

2000×1600×1600 |

|

38 |

ZW-1.85/19-25 |

2000 |

1.9 |

2.5 |

Circulating gas |

37 |

2000×1600×1600 |

|

39 |

DW-6.0/5 |

300 |

Normal |

0.5 |

Analytical gas |

37 |

2800×2200×1400 |

|

40 |

ZW-2.0/(2-3)-(12-16) |

360 |

0.2-0.3 |

1.2-1.6 |

Ethylene |

37 |

2000×1600×1200 |

|

41 |

ZW-1.2/(5-6)-20 |

400 |

0.5-0.6 |

2 |

Nitrogen |

37 |

2000×1600×1200 |

|

42 |

VW-3.0/(1.0-2.6)-8.0 |

420 |

0.1-0.26 |

0.8 |

Butadiene |

37 |

2200×1400×1500 |

|

43 |

ZW-1.5/2-35 |

210 |

0.2 |

3.5 |

Mixed gas |

37 |

2000×1600×1600 |

|

44 |

VW-0.21/(20-30)-250 |

270 |

2-3 |

25 |

Methane |

45 |

3200×2000×1600 |

|

45 |

VW-2.0/2-36 |

300 |

0.2 |

3.6 |

Mixed gas |

45 |

2200×1600×1500 |

|

46 |

ZW-2.5 /(6-16)-24 |

1380 |

0.6-1.6 |

2.4 |

Acrylic |

45 |

2200×1600×1500 |

|

47 |

ZW-3.0/10-16 |

1680 |

1 |

1.6 |

C4 |

45 |

2200×1600×1500 |

|

48 |

ZW-0.46 /(5-10)-250 |

200 |

0.5-1.0 |

25 |

Methane |

45 |

3100×2000×1475 |

|

49 |

ZW-0.4/(10-23)-80 |

350 |

1-2.3 |

8 |

Ethylene |

45 |

2200×1500×1500 |

|

50 |

DW-2.9/14.2-20 |

2220 |

1.42 |

2 |

Dry gas |

45 |

2600×2200×1400 |

|

51 |

DW-2.4/(0.5-5)-20 |

340 |

0.05-0.5 |

2 |

Chloromethane |

55 |

2600×2200×1400 |

|

52 |

VW-0.84/5-(150-200) |

250 |

0.5 |

15-20 |

Oxygen |

55 |

3100×2100×1750 |

|

53 |

ZW-2.9/14.2-20 |

220 |

1.42 |

2 |

Dry gas |

55 |

2100×1800×1700 |

|

54 |

VW-7.0/1.5-5 |

800-1000 |

0.15 |

0.5 |

Oxygen |

55 |

2200×1600×1600 |

|

55 |

ZW-1.8/80-85 |

7200 |

8 |

8.5 |

Helium |

75 |

2400×1800×1500 |

|

56 |

VW-10/8 |

600 |

Normal |

0.8 |

Ethyl chloride |

75 |

2400×1800×1500 |

|

57 |

VW-12.5/5 |

750 |

Normal |

0.5 |

Oxygen |

75 |

2400×1800×1500 |

|

58 |

VW-7.0/(0-0.05)-18 |

450 |

0-0.005 |

1.8 |

Trifluoroethane |

75 |

2400×1800×1500 |

|

59 |

DW-6.8/(0.05-0.2)-(14-16) |

400 |

0.005-0.02 |

1.4-1.6 |

Ethylene |

75 |

2400×1800×1500 |

|

60 |

VW-6/22 |

350 |

Normal |

2.2 |

Low temperature ethylene |

75 |

2400×1800×1500 |

|

61 |

DW-3.45/3.5-28 |

800 |

0.35 |

2.8 |

Mixed gas |

90 |

2400×1800×1500 |

|

62 |

VW-20.48/0.5-4 |

1600 |

0.05 |

0.4 |

Hydrogen sulfide |

110 |

3400×2200×1300 |

|

63 |

DW-19/4-6 |

4800 |

0.4 |

0.6 |

Circulating gas |

110 |

3400×2200×1300 |

|

64 |

VW-15/13 |

780 |

Normal |

1.3 |

Carbon monoxide |

132 |

2400×1800×1500 |

|

65 |

2VW/20/8 |

1020 |

Normal |

0.8 |

Coalgas |

132 |

4200×2200×1500 |

|

66 |

DW-22.4/0.5-4 |

1600 |

0.05 |

0.4 |

Hydrogen sulfide |

132 |

3400×2200×1300 |

|

67 |

DW-19/(0.05-0.1)-6.5 |

1000 |

0.005-0.01 |

0.65 |

Raw gas |

132 |

3400×2200×1300 |

|

68 |

DW-7.73/4-15 |

2000 |

0.4 |

1.5 |

C4 |

132 |

3400×2200×1600 |

|

69 |

VW-16/0.2-10 |

960 |

0.02 |

1 |

Oxygen |

132 |

3400×2200×1300 |

|

70 |

DW-21/ 0.1-6 |

1200 |

0.01 |

0.6 |

Analytical gas |

132 |

4200×2200×1500 |

|

71 |

VW-1.0/20-200 |

1080 |

2 |

20 |

Carbon dioxide |

160 |

4000×2000×1800 |

|

72 |

DW-3.0/3-250 |

500 |

0.3 |

25 |

Methane |

160 |

4000×2000×1800 |

|

73 |

VW-5.4/5-30 |

1650 |

0.5 |

3 |

Oxygen |

160 |

4800×2200×1300 |

|

74 |

DW-18/0.1-22 |

1020 |

0.01 |

2.2 |

Carbon dioxide |

185 |

5200×3000×1900 |

|

75 |

DW-10/1-30 |

1020 |

0.1 |

3 |

Phosphorus pentafluoride |

185 |

5200×3000×1900 |

|

76 |

VW-2.6/5-250 |

800 |

0.5 |

25 |

Methane |

185 |

3600×2200×1500 |

|

77 |

DW-67/1.5 |

3420 |

Normal |

0.15 |

Mixed gas |

185 |

3600×2200×1500 |

|

78 |

VW-2.1/10-250 |

1140 |

1 |

25 |

Coalbed methane |

200 |

5500×3200×2000 |

|

79 |

2VW-18/0.2-25 |

1110 |

0.02 |

2.5 |

Exhaust |

200 |

5500×3000×2000 |

|

80 |

2VW-33.4/8 |

1740 |

Normal |

0.8 |

Methyl chloride |

200 |

5500×3000×2000 |

|

81 |

DW-42/(2-3)-(3.5-4.5) |

6500 |

0.2-0.3 |

0.35-0.45 |

Vinyl chloride |

220 |

5500×3000×2000 |

|

82 |

DW-25/18 |

1300 |

Normal |

1.8 |

Difluoro Methane |

220 |

5500×3000×2000 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for OEM Diaphragm Compressor Manufacturers Suppliers – Chemical Process heavy duty Piston Compressor – Huayan , The product will supply to all over the world, such as: Chile, America, Malta, Our items have national accreditation requirements for qualified, high quality products, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Should any of these products be of interest to you, please letus know. We are going to be content to offer you a quotation up on receipt of your detailed needs.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.