OEM Hydrogen Refueling Station Compressor Factory – High Stable Belt Driven Ammonia unloading compressor – Huayan

OEM Hydrogen Refueling Station Compressor Factory – High Stable Belt Driven Ammonia unloading compressor – Huayan Detail:

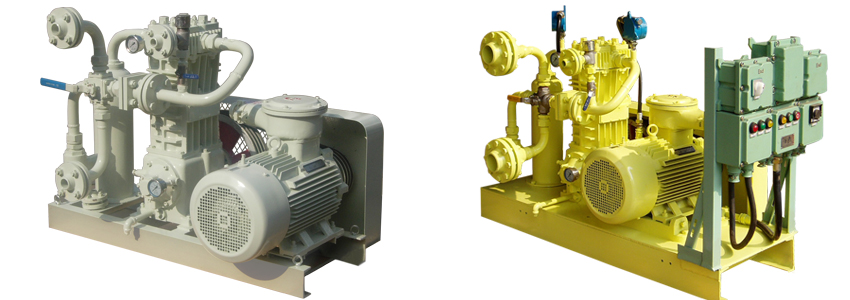

Ammonia unloading compressor

product description

This series of oil-free lubrication compressors is one of the products produced by our company. The product has the characteristics of low rotation speed, high component strength, stable operation, long service life, and convenient maintenance. Among them, the ZW series compressor is in the form of a unit. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, check valve, explosion-proof motor, and chassis. It has the characteristics of small size, lightweight, low noise, good airtightness, easy installation, and simple operation.

This product is mainly used for unloading, loading, refilling, gas recovery, and residual liquid recovery of LPG/C4, propylene, and liquid ammonia. It is widely used in gas, chemical, energy, and other industries, and is the key equipment for gas, chemical, energy, and other industries.

Note: In the process of unloading, the compressor pressurizes the gas from the storage tank and then presses it into the tank truck through the gas phase pipeline, and presses the liquid from the tank truck to the storage tank through the pressure difference of the gas phase to complete the unloading process. When the gas phase is pressurized, the temperature of the gas phase will increase. At this time, it is not necessary to perform forced cooling, because if the gas phase is compressed and then cooled, it is easy to liquefy and it is difficult to establish a pressure difference in the gas phase, which is not conducive to the replacement of the gas phase and the liquid phase. In short, it will cause an extension of the unloading process time. If residual gas recovery is required, a cooler can be used to forcibly cool the gas phase during the residual gas recovery operation in order to recover the residual gas as soon as possible.

The loading process is opposite to the unloading process.

|

NO |

Model |

(Nm3/h) |

Inlet pressure (Mpa) |

Outlet pressure (Mpa) |

Moter POWER (KW) |

Dimensions (mm) |

|

1 |

ZW-0.6/16-24 |

550 |

1.6 |

2.4 |

11 |

1000×580×870 |

|

2 |

ZW-0.8/16-24 |

750 |

1.6 |

2.4 |

15 |

1000×580×870 |

|

3 |

ZW-1.0/16-24 |

920 |

1.6 |

2.4 |

18.5 |

1000×580×870 |

|

4 |

ZW-1.5/16-24 |

1380 |

1.6 |

2.4 |

30 |

1000×580×870 |

|

5 |

ZW-2.0/16-24 |

1500 |

1.6 |

2.4 |

37 |

1000×580×870 |

|

6 |

ZW-2.5/16-24 |

1880 |

1.6 |

2.4 |

45 |

1000×580×870 |

|

7 |

ZW-3.0/16-24 |

2250 |

1.6 |

2.4 |

55 |

1000×580×870 |

|

8 |

ZW-0.8/10-16 |

450 |

1.0 |

1.6 |

11 |

1100×740×960 |

|

9 |

ZW-1.1/10-16 |

600 |

1.0 |

1.6 |

15 |

1100×740×960 |

|

10 |

ZW-1.35/10-16 |

750 |

1.0 |

1.6 |

18.5 |

1100×740×960 |

|

11 |

ZW-1.6/10-16 |

950 |

1.0 |

1.6 |

22 |

1400×900×1180 |

|

12 |

ZW-2.0/10-16 |

1200 |

1.0 |

1.6 |

30 |

1400×900×1180 |

|

13 |

ZW-2.5/10-16 |

1500 |

1.0 |

1.6 |

37 |

1400×900×1180 |

|

14 |

ZW-3.0/10-16 |

1800 |

1.0 |

1.6 |

45 |

1400×900×1180 |

|

15 |

ZW-0.6/16-24 |

550 |

1.6 |

2.4 |

11 |

1500×800×1100 |

|

16 |

ZW-0.8/16-24 |

750 |

1.6 |

2.4 |

15 |

1500×800×1100 |

|

17 |

ZW-1.0/16-24 |

920 |

1.6 |

2.4 |

18.5 |

1500×800×1100 |

|

18 |

ZW-1.5/16-24 |

1380 |

1.6 |

2.4 |

30 |

1600×900×1200 |

|

19 |

ZW-2.0/16-24 |

1500 |

1.6 |

2.4 |

37 |

1600×900×1200 |

|

20 |

ZW-2.5/16-24 |

1880 |

1.6 |

2.4 |

45 |

1600×900×1200 |

|

21 |

ZW-3.0/16-24 |

2580 |

1.6 |

2.4 |

55 |

1600×900×1200 |

|

22 |

ZW-3.5/16-24 |

3000 |

1.6 |

2.4 |

55 |

1600×900×1200 |

|

23 |

ZW-4.0/16-24 |

3500 |

1.6 |

2.4 |

75 |

1600×900×1200 |

|

24 |

ZW-0.2/10-25 |

100 |

1 |

2.5 |

5.5 |

1000×580×870 |

|

25 |

ZW-0.4/10-25 |

220 |

1 |

2.5 |

11 |

1000×580×870 |

|

26 |

ZW-0.6/10-25 |

330 |

1 |

2.5 |

15 |

1000×580×870 |

|

27 |

ZW-0.2/25-40 |

260 |

2.5 |

4 |

7.5 |

1000×580×870 |

|

28 |

ZW-0.4/25-40 |

510 |

2.5 |

4 |

15 |

1000×580×870 |

|

29 |

ZW-0.5/25-40 |

660 |

2.5 |

4 |

18.5 |

1000×580×870 |

|

30 |

ZW-0.3/20-30 |

300 |

2 |

3 |

7.5 |

1000×580×870 |

|

31 |

ZW-0.4/20-30 |

420 |

2 |

3 |

11 |

1000×580×870 |

|

32 |

ZW-0.5/20-30 |

540 |

2 |

3 |

15 |

1000×580×870 |

|

33 |

ZW-0.6/20-30 |

630 |

2 |

3 |

15 |

1000×580×870 |

|

34 |

ZW-1.6/20-30 |

1710 |

2 |

3 |

37 |

1400×900×1180 |

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with OEM Hydrogen Refueling Station Compressor Factory – High Stable Belt Driven Ammonia unloading compressor – Huayan , The product will supply to all over the world, such as: Cambodia, Johor, Malawi, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.