OEM Nitrogen Generator Bottle Filling Factory – High purity Nitrogen Generator System – Huayan

OEM Nitrogen Generator Bottle Filling Factory – High purity Nitrogen Generator System – Huayan Detail:

XUZHOU HUAYAN GAS EQUIPMENT CO.,LTD oxygen generator adopts Pressure Swing Adsorption technology to produce oxygen from compressed air .

HYO series Oxygen Generators are available in different standard models with capacity ranging from 3.0Nm3/h to 150 Nm3/hour at 93% ±2 purity .The design is made for round the clock 24/7 operation .

PSA Oxygen Plant with cylinder filing station is used for filling cylinders of any size up to 200 bar. The filing capacity ranges from 12 to 240 cylinders or more per day.

The system can be set up to fill the hospital pipeline directly and use the filling ramp as a backup system. Oxygen cylinders can be filled simultaneously or during hours with low consumption.

All-in-one oxygen generator systems are perfect for medium & small-sized township hospitals, community hospitals, clinics, oxygen therapy centers, laboratories, research institutes

All-in-one design;Assembled in factory; Plug and play to have medical oxygen with a 93%±2% purity Integrated refrigerated air dryer for effectively protecting molecular sieves to extend the useful life of the unit.

Our all-in-one oxygen generator systems has many years of experience with cutting edge technology makes the product development come true.

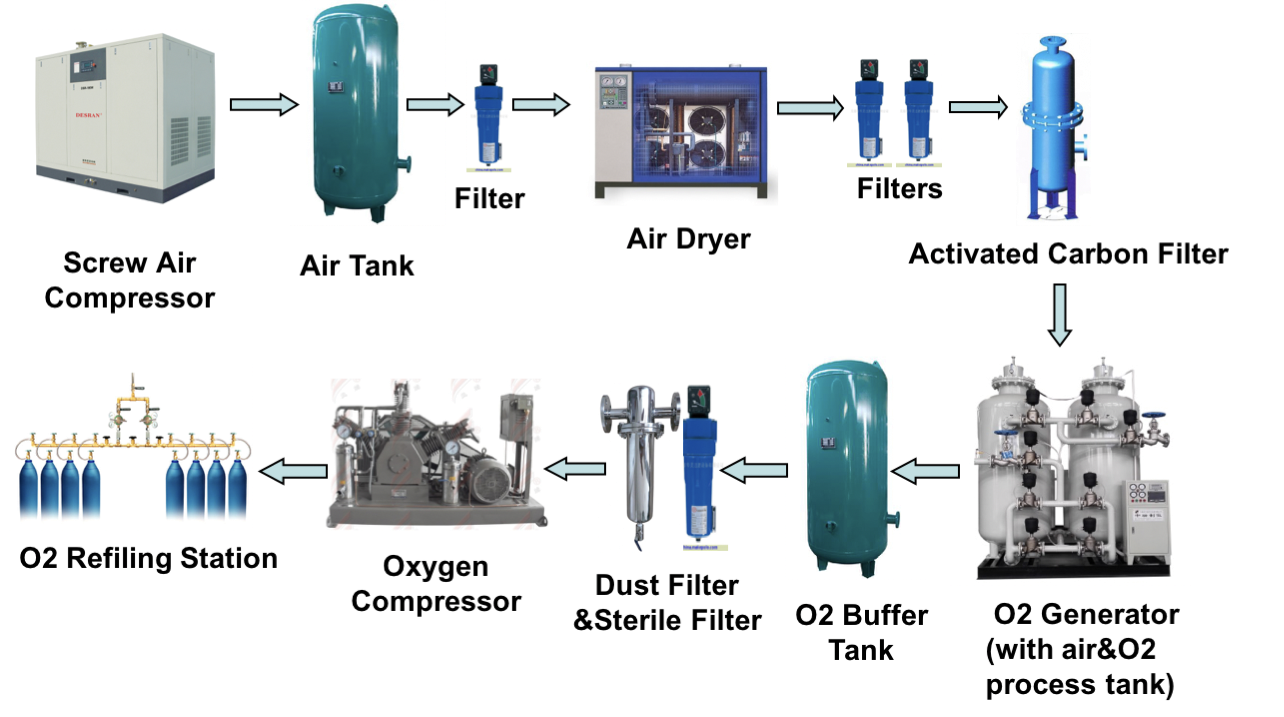

System Composition of All-in-One Oxygen Generator System

1)Air compressor: electric drive or generator drive, air cooled screw air compressor.

2) Air purification system: with air buffer tank, air dryer and filters, etc.

3) PSA oxygen generator: with adsorption towers, control system, etc.

4) Oxygen booster: can rise oxygen pressure up to 200Bar.

5) Cylinder refilling system (optional): with manifold and oxygen cylinders.

PSA all-in-one oxygen generator system uses clean compressed air as raw material and zeolite molecular sieve (ZMS) as adsorbent, to produce oxygen gas with Pressure Swing Adsorption (PSA)technology in normal temperature. ZMS is round granular adsorbent full of micro pores inside and outside.which has characteristic of selective adsorption. N2 has higher diffusion rate while O2 has lower, therefore N2 is adsorbed into ZMS while O2 is out of it. With controlling on/off state of the pneumatic valves by PLC, adsorbing under pressure and regenerating without pressure, to separate nitrogen and oxygen gas, and create continuous flow of oxygen with require purity.

Technical Specification:

- Flow rate: 3.0 Nm3/h to 150 Nm3/h

- Purity: 93% ±2 (based on customer’s requirements)

- Dew point: -50°C

- Operating temperature: 5°C – 45°C

Features of All-in-one Medical Mobile Oxygen Generator System

1)Adopt human-computer interface and intelligent control to make simple operation and supply qualified oxygen gas quickly.

2)High-efficiency filling technology of molecular sieve, to makes ZMS much tighter firmer and longer service life.

3)Adopt international famous brands PLC and pneumatic valves, to switch automatically and make operation more stable.

4)Pressure, purity and flowrate are stable and adjustable, can meet different requirements of customers.

5)Compact structure, nice appearance, and small occupation area.

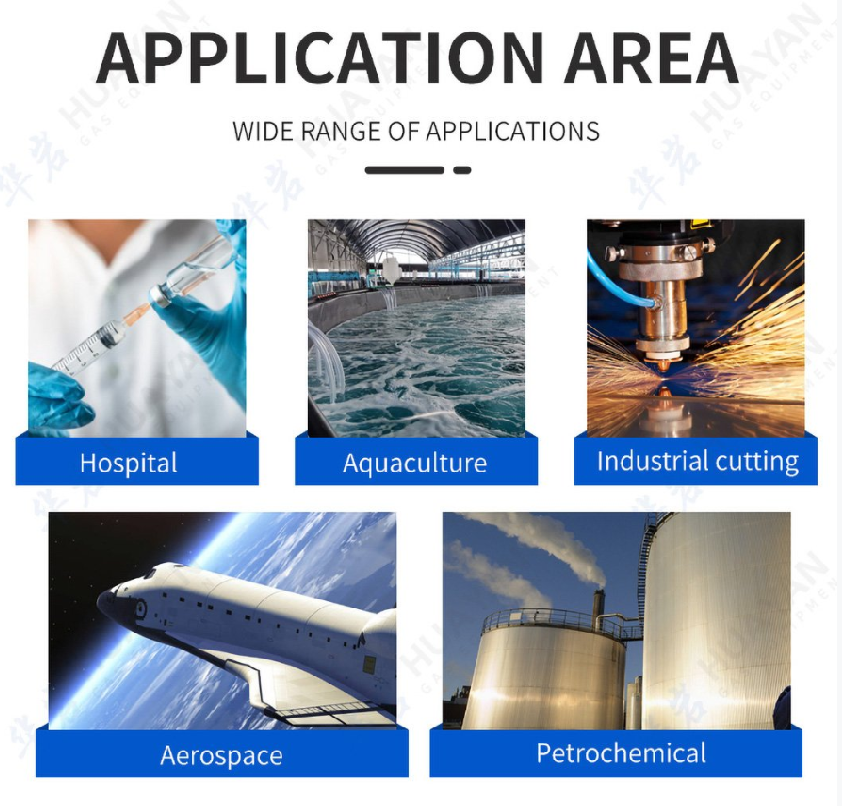

Applications of All-in-one Medical Mobile Oxygen Generator System

1)Sewage treatment: oxygen-enriched aeration for activated sludge, ponds oxygenation and ozone sterilization.

2)Glass melting: combustion-supporting dissolution, cutting to increase yield and extend the service life of stoves.

3)Pulp bleaching and paper making: changing chlorinated bleaching to oxygen-enriched bleaching with low cost, sewage treatment.

4)Non-ferrous metal metallurgy: oxygen-enriched smelting of steel, zinc, nickel, lead, etc. PSA technology is gradually taking the place of cryogenic technology.

5)Petrochemical and chemical industry: increasing the reaction speed and chemical production output by adopting oxygen-enriched oxidizing reaction.

6)Ore treatment: use oxygen in gold, etc. production process, to improve precious metal extraction efficiency.

7)Aquaculture: increasing dissolved oxygen in water by oxygen-enriched aeration to vastly improve fish yield, also can use oxygen when transport live fish.

8)Fermentation: replacing air with oxygen in fermentation to drastically improve efficiency.

9)Drinking water providing oxygen to ozone generator for sterilization.

10)Medical: oxygen bar, oxygen therapy, physical health care, etc.

Standard Model and Specification of All-in-one Medical Mobile Oxygen Generator System

|

MODEL |

PRESSURE |

OXYGEN FLOW |

PURITY |

CAPACITY FOR FILLING CYLINDERS PER DAY |

|

|

40L /150bar |

50L /200bar |

||||

|

HYO-3 |

150/200BAR |

3Nm³/h |

93%±2 |

12 |

7 |

|

HYO-5 |

150/200BAR |

5Nm³/h |

93%±2 |

20 |

12 |

|

HYO-10 |

150/200BAR |

10Nm³/h |

93%±2 |

40 |

24 |

|

HYO-15 |

150/200BAR |

15Nm³/h |

93%±2 |

60 |

36 |

|

HYO-20 |

150/200BAR |

20Nm³/h |

93%±2 |

80 |

48 |

|

HYO-25 |

150/200BAR |

25Nm³/h |

93%±2 |

100 |

60 |

|

HYO-30 |

150/200BAR |

30Nm³/h |

93%±2 |

120 |

72 |

|

HYO-40 |

150/200BAR |

40Nm³/h |

93%±2 |

160 |

96 |

|

HYO-45 |

150/200BAR |

45Nm³/h |

93%±2 |

180 |

108 |

|

HYO-50 |

150/200BAR |

50Nm³/h |

93%±2 |

200 |

120 |

|

HYO-60 |

150/200BAR |

60Nm³/h |

93%±2 |

240 |

144 |

How to get a quote for All-in-one Medical Mobile Oxygen Generator System ? Customized is accepted .

- O2 flow rate :______Nm3/h (how many cylinders do you want to fill per day(24 hours)

- O2 purity :_______%

- O2 discharge pressure :______ Bar

- Voltages and Frequency : ______ N/PH/HZ

- Application : _______

The Oxygen Generator System is consisted by .Air Compressor , Air Receive Tank ,Refrigerant Dryer &Precision Filters , Oxygen Generator ,Oxygen Buffer Tank , Sterile Filter,Oxygen Booster,Oxygen Filling Station .

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM Nitrogen Generator Bottle Filling Factory – High purity Nitrogen Generator System – Huayan , The product will supply to all over the world, such as: Nigeria, Burundi, Colombia, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.